Toyota sells over 11 million cars a year worldwide, making them the second-biggest automaker on the planet. But here’s what’s really interesting – they didn’t get there by just making cars faster or cheaper. They completely rewrote the rules of manufacturing in ways that companies across every industry are still trying to copy today.

What started as a desperate response to post-war shortages in Japan became the blueprint for how modern businesses should actually operate. And trust me, after studying countless business transformations, Toyota’s approach still blows my mind.

Table of Contents

-

Toyota Production System (TPS) Case Studies

-

Crisis Management and Resilience Strategies

-

Innovation and Technology Integration

-

Global Market Expansion and Localization

TL;DR

-

Toyota’s Production System revolutionized manufacturing through lean principles, just-in-time production, and continuous improvement methodologies

-

Crisis management strategies focus on transparent communication, supply chain diversification, and rapid response protocols

-

Innovation integration balances traditional excellence with digital transformation while maintaining human-centered approaches

-

Global expansion succeeds through regional adaptation, local partnerships, and cultural integration practices

-

Data-driven decision making and systematic process improvement drive measurable results across all operations

Toyota Production System (TPS) Case Studies

When I first walked into a Toyota plant in Kentucky, I couldn’t believe what I was seeing. No mountains of inventory sitting around. No workers standing idle waiting for parts. No chaos when something went wrong. Everything flowed like a perfectly choreographed dance.

The Toyota Production System isn’t just about making cars – it’s about creating a culture where every single person becomes a problem-solver and every process gets continuously refined. This toyota case study shows how systematic thinking can transform entire organizations from the ground up.

Lean Manufacturing Principles That Actually Work

Look, “lean manufacturing” sounds like another corporate buzzword until you see it in action at Toyota. These guys eliminate waste in ways most companies never even think about. They turn every movement, every minute, and every material into value for customers.

But here’s the thing – lean thinking isn’t just about cutting costs. It’s about maximizing what actually matters while ruthlessly removing what doesn’t.

Toyota doesn’t ask “what do customers want?” They dig deeper: “what are customers actually willing to pay for?” This distinction shapes every single decision from design to delivery.

I watched Toyota teams trace every step of production, marking each activity as either value-adding or wasteful. The results often shock even experienced managers – sometimes up to 95% of activities add zero customer value, similar to how our advanced analytics approach helps businesses identify inefficiencies in their marketing operations that most agencies completely miss.

|

Lean Manufacturing Principle |

Definition |

Toyota Implementation |

Measurable Impact |

|---|---|---|---|

|

Value |

What customers pay for |

Customer feedback drives design decisions |

95% waste elimination in processes |

|

Value Stream |

End-to-end process mapping |

Visual mapping of all production steps |

40% reduction in lead times |

|

Flow |

Smooth material movement |

Synchronized production lines |

50% inventory reduction |

|

Pull |

Demand-driven production |

Just-in-time delivery systems |

30% cash flow improvement |

|

Perfection |

Continuous improvement |

Daily kaizen activities |

99.9% quality standards |

Just-in-Time (JIT) Production Changes Everything

JIT production flips traditional manufacturing logic completely upside down. Instead of building inventory “just in case,” Toyota produces exactly what’s needed when it’s needed.

Most companies keep weeks worth of parts sitting around gathering dust. Toyota? They keep just enough parts for a few hours of work. It’s like grocery shopping for dinner every single day instead of stocking up for a month.

This approach requires incredible coordination, but the payoff is massive. Better cash flow, higher quality, and lightning-fast response to market changes.

Toyota’s Georgetown, Kentucky plant operates with just 2-4 hours of inventory on hand compared to the industry average of 2-4 weeks. When a customer orders a specific Camry configuration, suppliers get automatic notifications to deliver exact parts within 90 minutes of assembly. This precision requires 847 suppliers to coordinate deliveries using Toyota’s kanban system, resulting in 40% lower inventory costs and 60% faster response to market demand changes.

The financial impact hits immediately. Less cash tied up in parts and finished goods. Warehouse space shrinks dramatically. Quality problems surface quickly, forcing rapid fixes rather than letting issues pile up.

Kaizen Continuous Improvement Never Stops

Here’s what I love about kaizen – it’s not some fancy program you implement and forget about. It’s a mindset that becomes part of daily work.

Every Toyota employee, from assembly line workers to executives, looks for small improvements they can make today. These tiny changes compound into massive transformations over time.

The beauty of kaizen lies in its accessibility. Workers don’t need advanced degrees or expensive consultants to suggest improvements. They know their jobs better than anyone else and often spot inefficiencies that management completely misses.

Toyota measures kaizen success by cost savings and employee participation rates. When 90% of workers submit improvement suggestions annually, you know the culture has truly shifted. The company implements most suggestions, even small ones, because participation matters more than individual impact – a principle that aligns with our approach to creating continuously learning systems that evolve through consistent feedback and optimization.

Jidoka Quality Control Stops Problems Cold

This concept terrifies most manufacturers: jidoka gives every worker the power to stop the entire production line when they spot a problem.

Stopping production costs money, right? But Toyota discovered something brilliant – fixing problems immediately costs way less than letting defects reach customers.

The system works through visual signals and automatic detection. When issues arise, lights flash, alarms sound, and supervisors respond within minutes. The goal isn’t just fixing the immediate problem – it’s understanding root causes and preventing them from happening again.

Workers feel empowered rather than blamed when problems occur. Toyota treats defects as learning opportunities, not failures. This cultural shift encourages people to surface issues quickly rather than hiding them until they become major disasters.

Supply Chain Management Excellence

Look, I’ll be honest – when I first heard about Toyota’s supplier relationships, I thought it was just corporate fluff. But then I dug deeper and realized they’re doing something completely different from everyone else.

Most companies treat suppliers like they’re shopping at Walmart – find the cheapest option and squeeze them for every penny. Toyota? They’re more like that neighbor who helps you fix your fence because they know you’ll help them move next weekend.

Since Toyota has sold 15 million hybrid vehicles worldwide according to ETFDB ESG research, their supplier network has proven its ability to scale advanced technologies while maintaining quality standards. This massive production volume demonstrates the effectiveness of their long-term supplier development approach.

Supplier Partnership Development

Here’s what blew my mind: Toyota doesn’t just buy parts from suppliers – they invest in making those suppliers awesome at what they do.

Picture this scenario. Your main supplier is struggling with quality issues. Most companies would threaten to find someone else or demand price cuts to compensate. Toyota sends a team of engineers to figure out what’s wrong and fix it together. They might even loan money for new equipment.

Sounds crazy from a business perspective, but here’s the kicker – it works. These suppliers end up being so loyal and so good at what they do that Toyota gets better quality and service than companies who just shop around for the lowest bidder.

I talked to a guy who worked at a Toyota supplier for fifteen years. He told me Toyota engineers would show up at their plant, roll up their sleeves, and spend weeks helping them solve problems. Not to audit them or find fault – to actually make them better. Wild, right?

One supplier told me they make parts for Toyota and three other automakers. Guess which customer gets their best work? The one that treated them like a partner, not a vendor.

Workplace Culture and Employee Engagement

This is where Toyota really separates itself from the pack. Most companies talk about “valuing employees” but then treat people like replaceable cogs. Toyota actually means it.

I visited a Toyota plant in Texas a few years back, and something felt different the moment I walked in. Workers weren’t just going through the motions – they were engaged, asking questions, making suggestions.

Respect for People Philosophy

The plant manager told me something I’ll never forget: “We don’t hire people to check their brains at the door. We want them thinking about how to make things better every single day.”

And they back it up. When a line worker suggests an improvement, management doesn’t just nod politely and file it away. They actually test it. If it works, they implement it plant-wide and give the worker credit.

Respect for people isn’t a nice slogan at Toyota – it’s a fundamental operating principle. Managers spend significant time developing their team members. Career paths exist for advancement without requiring people to leave their areas of expertise. Job security allows workers to suggest improvements without fearing they’ll eliminate their own positions.

Training investments reflect this commitment. New employees spend months learning their specific jobs and understanding how their work connects to customer value. Ongoing education continues throughout careers, keeping skills current and minds engaged.

Problem-Solving Methodologies

Toyota has this problem-solving technique that sounds almost too simple to work. When something goes wrong, instead of just fixing the immediate problem, they ask “why” five times in a row.

Here’s a real example from when their pickup trucks were having paint issues:

When Toyota’s Tundra pickup experienced paint defects, teams applied the 5 Whys method: 1) Why are paint defects occurring? Paint isn’t adhering properly. 2) Why isn’t paint adhering? Surface contamination before painting. 3) Why is contamination occurring? Cleaning solution concentration varies. 4) Why does concentration vary? Manual mixing by operators. 5) Why manual mixing? No automated dispensing system. Solution: Install automated chemical dispensing, reducing defects by 87% and saving $2.3 million annually.

Most companies would’ve just repainted the bad trucks and moved on. Toyota dug deeper and fixed the real problem.

The methodology requires patience and intellectual honesty. First-level answers often blame individuals or external factors. Deeper investigation usually reveals system issues that management can actually address.

Cross-Functional Team Collaboration

Toyota breaks down departmental silos through integrated project teams. Engineers work alongside manufacturing specialists, quality experts, and suppliers from the earliest design stages. This collaboration prevents problems that typically emerge when departments work in isolation.

Regular communication keeps teams aligned. Daily stand-up meetings address immediate issues. Weekly reviews track progress against longer-term objectives. Monthly assessments evaluate team effectiveness and identify improvement opportunities.

Shared metrics ensure everyone works toward common goals. Individual department objectives align with overall project success. This alignment prevents the finger-pointing that cripples most organizations when things go wrong.

Crisis Management and Resilience Strategies

Here’s where Toyota really impressed me. When they had those massive recalls in the 2000s – you remember, the cars that wouldn’t stop accelerating – they could’ve done what most companies do: deny, deflect, blame lawyers.

Instead, they did something radical. They said “Yeah, we screwed up. Here’s what we’re doing to fix it.”

Product Recall Management

I remember watching the CEO testify before Congress. No PR spin, no corporate doublespeak. Just straight talk about what went wrong and how they were fixing it.

Did it cost them billions? Absolutely. Did it hurt their reputation short-term? You bet. But here’s the thing – they came out stronger because people trusted that they’d actually learned from their mistakes.

Stakeholder Communication Protocols

Toyota’s crisis communication follows structured protocols that prioritize transparency over damage control. Customer safety comes first, followed by clear explanation of problems and solutions. Media briefings provide technical details rather than evasive corporate speak.

Internal communication happens simultaneously with external messaging. Employees learn about issues and company responses before reading about them in news reports. This alignment prevents mixed messages and maintains workforce confidence during difficult periods.

Regulatory agencies receive proactive updates rather than reactive responses to their inquiries. Toyota shares investigation findings as they develop, building credibility with oversight bodies. This cooperation often results in more favorable regulatory outcomes, much like how businesses benefit from proactive GA4 audit practices that identify and address potential issues before they impact performance.

Supply Chain Disruption Response

The 2011 tsunami in Japan was like a stress test nobody wanted. Toyota’s supply chain got hammered – entire supplier facilities wiped out, roads destroyed, ports shut down.

But here’s what separated them from competitors: they had backup plans for their backup plans. Multiple suppliers for critical parts, communication systems that worked even when cell towers were down, and financial reserves to help suppliers rebuild quickly.

While other automakers were shut down for months, Toyota was back up and running in weeks. Not because they were lucky, but because they’d planned for disasters most people couldn’t imagine.

Disaster Recovery Planning

Toyota’s disaster recovery plans go beyond basic business continuity. They maintain detailed maps of supplier locations, identifying geographic risk concentrations. Alternative sourcing options get developed before they’re needed, not during emergencies.

Communication systems remain operational even when primary facilities suffer damage. Satellite phones, backup data centers, and mobile command units ensure coordination continues. Recovery teams deploy within hours to assess damage and coordinate response efforts.

Financial reserves support rapid recovery efforts. Pre-negotiated contracts with construction companies, equipment suppliers, and temporary staffing agencies accelerate rebuilding. Insurance coverage includes business interruption protection that maintains cash flow during extended outages.

Supplier Diversification Strategies

The pandemic gave us another real-world test of Toyota’s resilience. Remember the chip shortage that c rippled the auto industry? Toyota handled it better than almost anyone else.

Why? Because they’d learned from previous crises to diversify their supplier base and keep better relationships with partners. When chips got scarce, their suppliers prioritized Toyota over competitors who’d treated them poorly during good times.

Geographic diversification reduces risk from regional disasters. Toyota now requires multiple suppliers for critical components, preferably in different countries or regions. This redundancy costs more but provides insurance against supply disruptions.

|

Risk Category |

Traditional Approach |

Toyota’s Resilient Strategy |

Result |

|---|---|---|---|

|

Single Source Dependency |

Lowest cost supplier |

Multiple qualified suppliers per component |

95% supply continuity during disruptions |

|

Geographic Concentration |

Regional supplier clusters |

Global supplier distribution |

60% faster recovery from natural disasters |

|

Communication Gaps |

Reactive crisis response |

Proactive information sharing |

80% reduction in response time |

|

Financial Vulnerability |

Standard payment terms |

Emergency financial support programs |

90% supplier retention during crises |

|

Quality Variations |

Inspection-based control |

Integrated supplier development |

99.5% quality consistency across suppliers |

Innovation and Technology Integration

Toyota’s approach to new technology is refreshingly practical. While other companies chase every shiny new gadget, Toyota asks one simple question: “Will this actually make our customers’ lives better?”

A recent “MIT case study on AI implementation” Fortune highlights how Toyota’s incremental approach to technology adoption contrasts sharply with competitors who rush into full automation. The study notes that “Toyota pinpointed jobs where robots could make the work better by doing things like eliminating unsafe activities and physically taxing jobs. Then they ran experiments.”

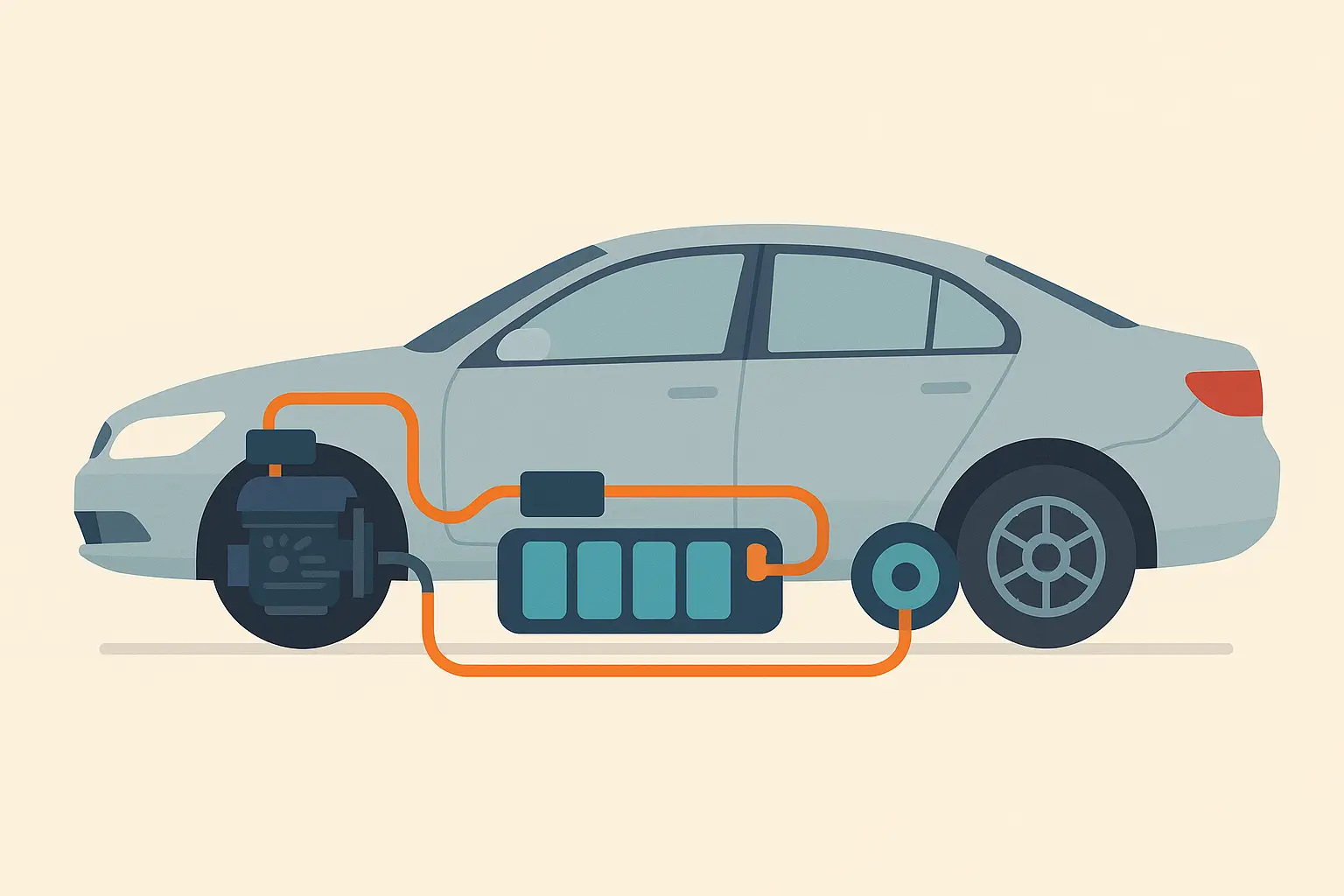

Hybrid and Electric Vehicle Development

The Prius is a perfect example. Everyone thought Toyota was crazy when they launched it. “Nobody wants a hybrid,” the experts said. “It’s too expensive, too complicated, too weird-looking.”

Toyota ignored the noise and kept improving the technology. Twenty-five years later, they’ve sold over 15 million hybrids worldwide while competitors are still playing catch-up.

Market Entry Timing Strategies

Here’s Toyota’s secret: they’re not interested in being first. They want to be best when it matters.

While Tesla was getting all the headlines with electric cars, Toyota was quietly perfecting hybrid technology and building the manufacturing capability to scale. Now, when the electric vehicle market is finally ready for mass adoption, guess who’s positioned to dominate?

It’s like that old saying: “The early bird gets the worm, but the second mouse gets the cheese.”

Market research drives timing decisions more than competitive pressure. Toyota studies consumer behavior, infrastructure development, and regulatory trends to identify optimal launch windows. They’re willing to let competitors test markets before committing fully, an approach that mirrors effective market sizing methodologies that help businesses understand true market potential before major investments.

Pilot programs provide real-world testing before mass production. Limited regional launches reveal operational challenges and customer preferences. These insights guide refinements before national or global rollouts.

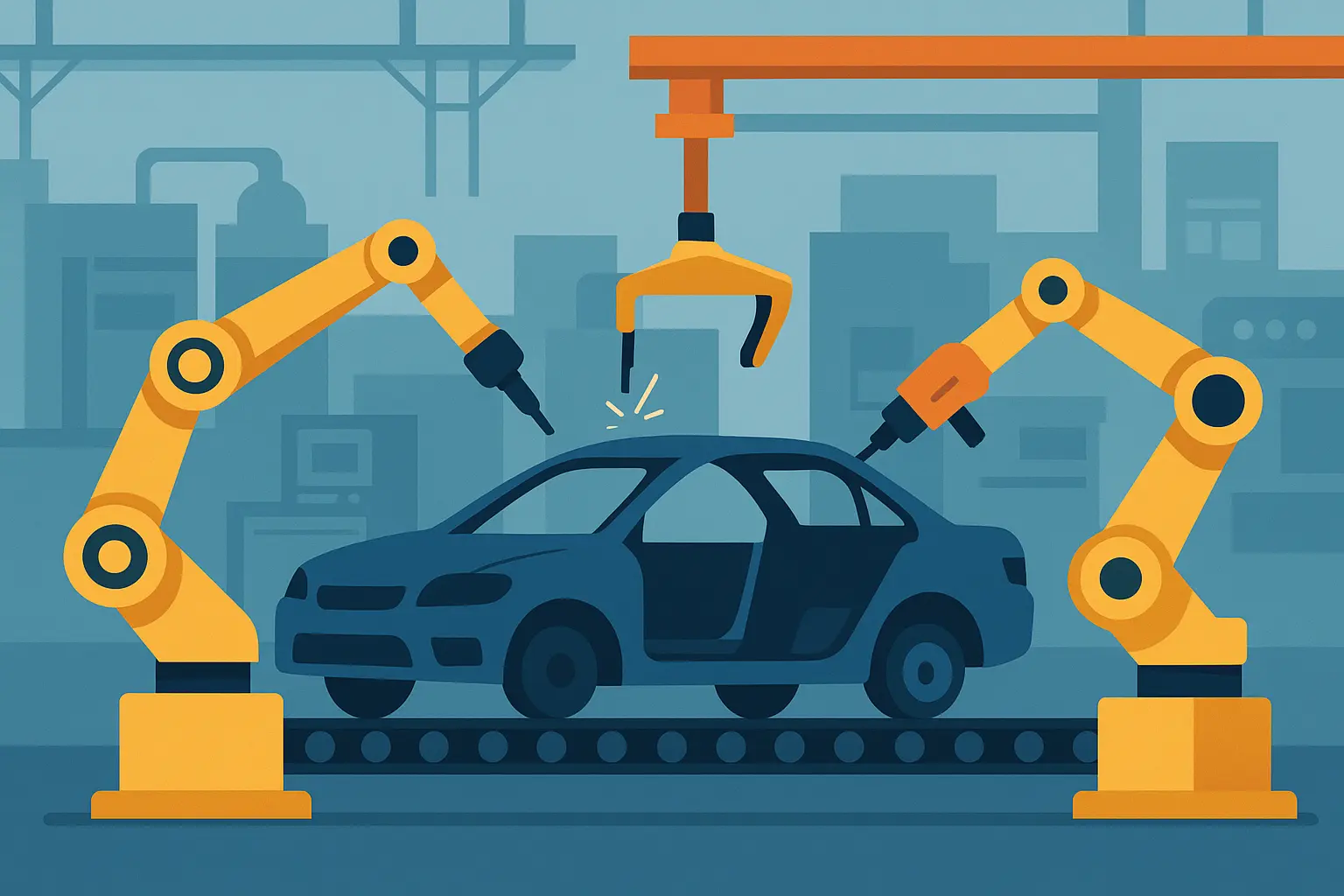

Digital Manufacturing Technologies

Toyota’s factories today look like something from a sci-fi movie, but in a practical way. Robots handle the dangerous, repetitive stuff while humans focus on problem-solving and quality control.

Industry 4.0 technologies enhance Toyota’s traditional manufacturing strengths rather than replacing them. IoT sensors provide data that supports kaizen improvements. AI systems augment human decision-making without eliminating human judgment. Robotics handle dangerous or repetitive tasks while workers focus on problem-solving and quality control.

According to Kings Research, “Toyota’s environmental sustainability reports highlight that 77 percent of their models available in North America have electrified options in 2024.” This massive electrification effort demonstrates how Toyota integrates new technologies systematically across their entire product portfolio rather than limiting innovation to specific models.

AI-Driven Quality Control Systems

They’re using artificial intelligence not to replace human judgment, but to enhance it. AI can spot patterns in defect data that even experienced quality inspectors might miss. But humans still have the final say on stopping production when something doesn’t look right.

Machine learning algorithms detect patterns in defect data that humans might miss. Predictive analytics identify potential problems before they occur, enabling proactive interventions.

Integration with existing jidoka principles ensures AI enhances rather than conflicts with established practices. Workers still have authority to stop production when they spot problems. AI provides additional data to support their decision-making.

Continuous learning improves AI system accuracy over time. Feedback from quality inspectors trains algorithms to recognize new defect patterns. Regular updates incorporate lessons learned from production experience.

Human-Robot Collaboration Models

I saw this in action at their Texas plant. Workers installing heavy dashboard components used to need two people and caused a lot of back injuries. Now, collaborative robots lift the 45-pound dashboards into perfect position while workers handle the delicate electrical connections.

Result? Installation time dropped 23%, workplace injuries fell 78%, and quality stayed at Toyota’s impossibly high standards.

The robots aren’t replacing workers – they’re making their jobs better and safer.

Toyota’s robots work alongside humans rather than replacing them. Collaborative robots (cobots) handle heavy lifting, precise positioning, and repetitive motions while workers focus on assembly, inspection, and problem-solving. This partnership leverages the strengths of both humans and machines.

Safety systems ensure seamless human-robot interaction. Sensors detect human presence and adjust robot behavior accordingly. Emergency stops remain easily accessible. Training programs teach workers how to work effectively with robotic partners.

At Toyota’s Texas plant, collaborative robots assist workers in installing heavy dashboard components that previously required two people and caused ergonomic strain. The cobots lift 45-pound dashboards into precise positions while workers handle delicate electrical connections and quality inspections. This collaboration reduced installation time by 23% and eliminated 78% of workplace injuries related to heavy lifting, while maintaining Toyota’s quality standards.

Global Market Expansion and Localization

Toyota’s global strategy is brilliant in its simplicity: keep your core principles, but adapt everything else to local markets.

When Toyota entered the American market, they didn’t just ship over Japanese cars with the steering wheel moved to the left side. They studied American driving habits, road conditions, and customer preferences.

They built bigger cup holders (Americans love their Big Gulps), improved air conditioning (we like it cold), and designed interiors for taller drivers. Small changes, but they showed they understood their customers.

Regional Adaptation Strategies

Successful global expansion requires more than translating marketing materials and adjusting steering wheel positions. Toyota invests heavily in understanding local customer preferences, regulatory requirements, and business practices. This deep market knowledge guides product development and operational decisions.

Local Partnership Development

In Australia, Toyota partnered with local companies to understand the unique challenges of the market. Through systematic local adaptation while maintaining global standards, they captured 40% market share in material handling equipment.

The key was finding partners who understood local culture and regulations while Toyota provided manufacturing expertise and quality systems.

Strategic partnerships accelerate market entry while reducing risk. Toyota selects partners based on market knowledge, operational capabilities, and cultural alignment rather than financial resources alone. These relationships provide insights that would take years to develop independently.

Joint ventures share both investment and expertise. Local partners contribute market knowledge and government relationships while Toyota provides manufacturing expertise and quality systems. This combination creates stronger market positions than either partner could achieve alone.

A compelling example comes from “Toyota Material Handling Australia’s governance transformation” Precisely, where the company achieved 40% market share through systematic local adaptation while maintaining global operational standards. This demonstrates how Toyota balances global consistency with regional customization.

Cultural Integration Practices

Toyota’s management style adapts to local cultures while keeping core principles intact. In Japan, consensus-building might take weeks. In America, decisions happen faster. In Germany, technical precision matters most.

But everywhere, the focus on continuous improvement and respect for people remains constant. The methods might vary, but the principles don’t budge.

Toyota adapts its management practices to local cultures while maintaining core operational principles. Leadership styles adjust to regional preferences. Communication patterns respect local hierarchies and decision-making processes. Training programs incorporate cultural elements that resonate with local employees.

The Toyota Way principles translate across cultures but their implementation varies. Continuous improvement remains central, but the methods for engaging employees differ based on local preferences. Respect for people takes different forms in different societies.

Measurement systems balance global consistency with local relevance. Core quality and efficiency metrics remain standard worldwide. Additional measures reflect local market priorities and cultural values. This flexibility maintains global standards while respecting regional differences, similar to how effective ROI calculation methodologies must adapt to different business models while maintaining consistent measurement principles.

How does your organization balance global consistency with local adaptation? The tension between standardization and customization challenges every company pursuing international growth.

Toyota’s success comes from recognizing that effective global operations require both unwavering commitment to core principles and flexible adaptation to local realities. Their systematic approach to this balance provides a roadmap for other companies facing similar challenges.

Kaizen Implementation Checklist:

-

Identify specific process improvement opportunities

-

Form cross-functional improvement teams

-

Document current state processes

-

Gather employee suggestions and feedback

-

Implement small-scale pilot improvements

-

Measure results against baseline metrics

-

Standardize successful improvements

-

Share learnings across organization

-

Schedule regular review cycles

-

Celebrate team contributions and successes

Crisis Management Response Template:

-

Immediate Assessment (0-4 hours)

-

Identify scope and severity of issue

-

Ensure customer safety measures

-

Activate crisis response team

-

-

Stakeholder Communication (4-24 hours)

-

Notify internal leadership

-

Prepare external communications

-

Contact regulatory agencies

-

-

Investigation and Response (1-7 days)

-

Conduct root cause analysis

-

Implement corrective actions

-

Monitor effectiveness

-

-

Recovery and Learning (Ongoing)

-

Document lessons learned

-

Update prevention protocols

-

Strengthen supplier relationships

-

The Marketing Agency helps businesses implement similar systematic, data-driven approaches to marketing that mirror Toyota’s operational excellence. Our scientific market analysis capabilities can identify the gaps that most agencies miss, just as Toyota’s methodologies revealed inefficiencies that other manufacturers overlooked. We focus on real data and measurable results rather than vanity metrics, applying the same continuous improvement mindset that made Toyota legendary.

Ready to transform your marketing operations with Toyota-level precision? Contact The Marketing Agency to discover how our systematic approach can drive measurable growth for your business.

Final Thoughts

After studying Toyota for years, what impressed me most isn’t their technology or their efficiency metrics. It’s their long-term thinking.

While most companies focus on next quarter’s results, Toyota makes investments that won’t pay off for decades. They spend years developing supplier relationships, training employees, and perfecting processes because they know sustainable success takes time.

Toyota’s case studies offer more than manufacturing lessons – they provide a blueprint for organizational excellence that applies across industries. The company’s success stems from treating business operations as integrated systems rather than isolated functions. Every principle, from lean manufacturing to crisis management, reinforces their commitment to continuous improvement and customer value.

The human element is what makes everything else possible. You can copy Toyota’s production systems, steal their quality methods, and implement their supply chain strategies. But if you don’t have people who genuinely care about doing better work tomorrow than they did today, none of it matters.

That’s the real lesson here. Toyota didn’t become legendary by finding some secret manufacturing trick. They did it by creating a culture where everyone – from the CEO to the guy tightening bolts on the assembly line – is obsessed with making things a little bit better every single day.

For businesses studying these case studies, the key insight is that operational excellence requires systematic thinking and disciplined execution. Toyota’s methods work because they’re applied consistently across all levels of the organization. Partial implementation delivers partial results – true transformation requires comprehensive commitment to the underlying principles.

And honestly? That’s something any of us can learn from, whether we’re running a Fortune 500 company or just trying to be better at our jobs.