A few months ago, I was chatting with a plant manager at a trade show, and he mentioned something that stopped me cold: three-quarters of his peers are already using AI in some form. I’ll be honest – I thought we were still years away from this being mainstream. Turns out, I was dead wrong.

The results speak for themselves. Among manufacturers who’ve actually deployed AI technology, 72% report they’re saving real money and getting more done with less. We’re not talking about tiny improvements here – these are game-changing transformations that are reshaping entire industries.

What you’ll discover in these 25 case studies isn’t just theoretical potential. These are real companies, real implementations, and real results that prove AI in manufacturing has moved way beyond the “let’s see if this works” phase.

Table of Contents

-

TL;DR: Key Takeaways

-

What Makes a Manufacturing AI Case Study Worth Your Time?

-

Predictive Maintenance: When Machines Tell You What They Need

-

Quality Control Revolution: AI Eyes That Never Blink

-

Production Optimization: The Science of Perfect Processes

-

Supply Chain Intelligence: Moving Beyond Guesswork

-

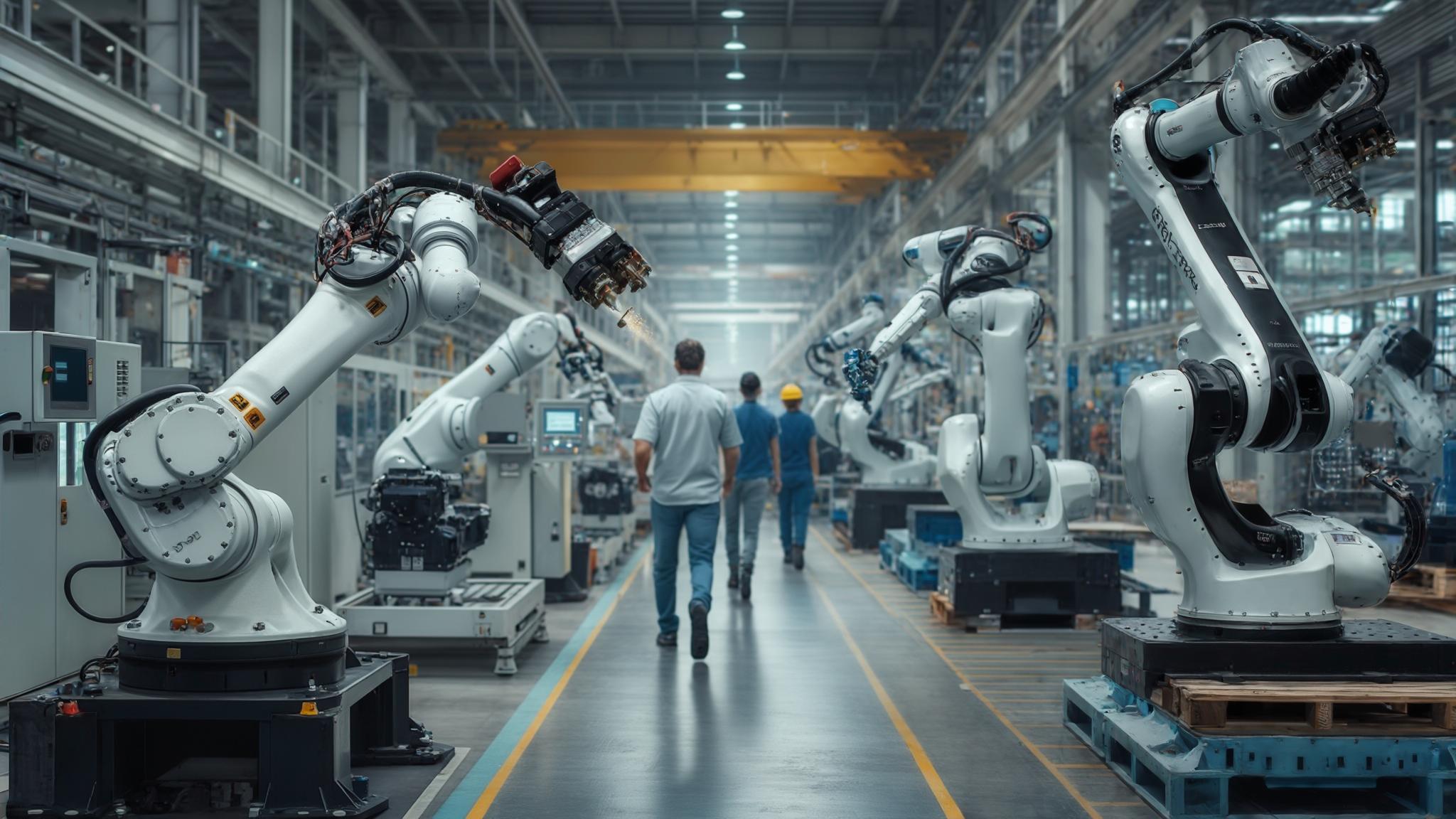

Human-Robot Collaboration: Safety Meets Productivity

-

Energy Management: The Green AI Revolution

-

How to Evaluate These Case Studies for Your Business

-

Why The Marketing Agency Matters for AI-Forward Manufacturers

TL;DR: Key Takeaways

-

Predictive maintenance AI can deliver $2 billion in annual savings (GE’s Predix platform proves it works at massive scale)

-

Quality control systems catch 90% more defects while speeding up inspections by 50%

-

Production optimization through AI typically delivers 8-25% improvements in getting more done with less

-

Supply chain AI implementations show consistent 15-25% cost cuts across multiple industries

-

Human-robot collaboration reduces workplace injuries by 60-70% while actually boosting productivity

-

Energy management AI can slash consumption by 40% (Google’s data centers lead the way)

-

ROI timelines range from 6 months to 2.5 years, but let’s be real – most take 12-18 months if everything goes right

-

Success factors include solid data infrastructure, getting your people on board, and keeping humans in the loop

What Makes a Manufacturing AI Case Study Worth Your Time?

Look, I’ve seen too many manufacturers get swept up in impressive-sounding implementations that don’t translate to their specific situations. Here’s what separates the wheat from the chaff when you’re evaluating whether an AI success story actually matters for your business.

Understanding the strategic importance of data-driven decision making is crucial when evaluating advanced analytics strategic growth opportunities in manufacturing AI implementations.

|

Evaluation Criteria |

High Value |

Medium Value |

Low Value |

|---|---|---|---|

|

ROI Timeline |

6-12 months |

12-24 months |

24+ months |

|

How Much of a Headache |

Software integration |

Hardware + software |

Complete system overhaul |

|

Data Requirements |

Works with what you have |

Minor upgrades needed |

Build everything from scratch |

|

Vendor Track Record |

Proven at scale |

Limited deployments |

Experimental technology |

|

Risk Level |

Low operational risk |

Moderate risk |

High operational risk |

ROI That Actually Makes Sense

The best case studies show you the money trail. We’re talking about results you can point to on a spreadsheet – productivity gains you can measure, cost cuts that show up on your bottom line, quality improvements that reduce warranty claims.

Payback periods matter more than you might think. Some implementations pay for themselves in six months, others take two and a half years. Neither’s inherently better, but you need to know which category you’re entering. And here’s what nobody tells you: those 6-month payback stories? They’re usually the exception, not the rule. Most places I’ve worked with see real results somewhere between 12-18 months, and that’s if everything goes right. Which it rarely does.

Technical Reality Check

Data requirements can make or break your AI project. The most successful implementations work with the data infrastructure you already have (or can reasonably build without breaking the bank).

Your AI solution needs to play nice with your existing manufacturing systems, not replace everything you’ve built over decades. I’ve watched million-dollar AI systems gather dust because nobody thought about how they’d integrate with 20-year-old PLCs.

Scalability determines whether you’re solving one problem or transforming your entire operation. The best case studies show clear paths from pilot projects to enterprise-wide deployment.

Implementation Complexity

Resource requirements go beyond just money. You need the right people, adequate time, and realistic expectations about organizational change.

Here’s what nobody tells you about AI implementation: your biggest enemy isn’t the technology – it’s your own people. Change management separates successful AI implementations from expensive failures. The companies that nail this part treat AI adoption as a people problem, not just a technology problem.

Timeline expectations need to be grounded in reality. Rush the implementation, and you’ll likely end up with expensive disappointment.

Consider a mid-sized automotive parts manufacturer I worked with who was evaluating AI quality control systems. They started looking at BMW’s visual inspection case study but realized their production volume (1,000 parts/day vs BMW’s 1,000+ vehicles/day) meant a simpler computer vision system would deliver better ROI. Instead of implementing BMW’s complex multi-camera setup, they chose a single-camera system that achieved 85% defect detection (vs BMW’s 99.7%) but paid for itself in 8 months rather than 2 years.

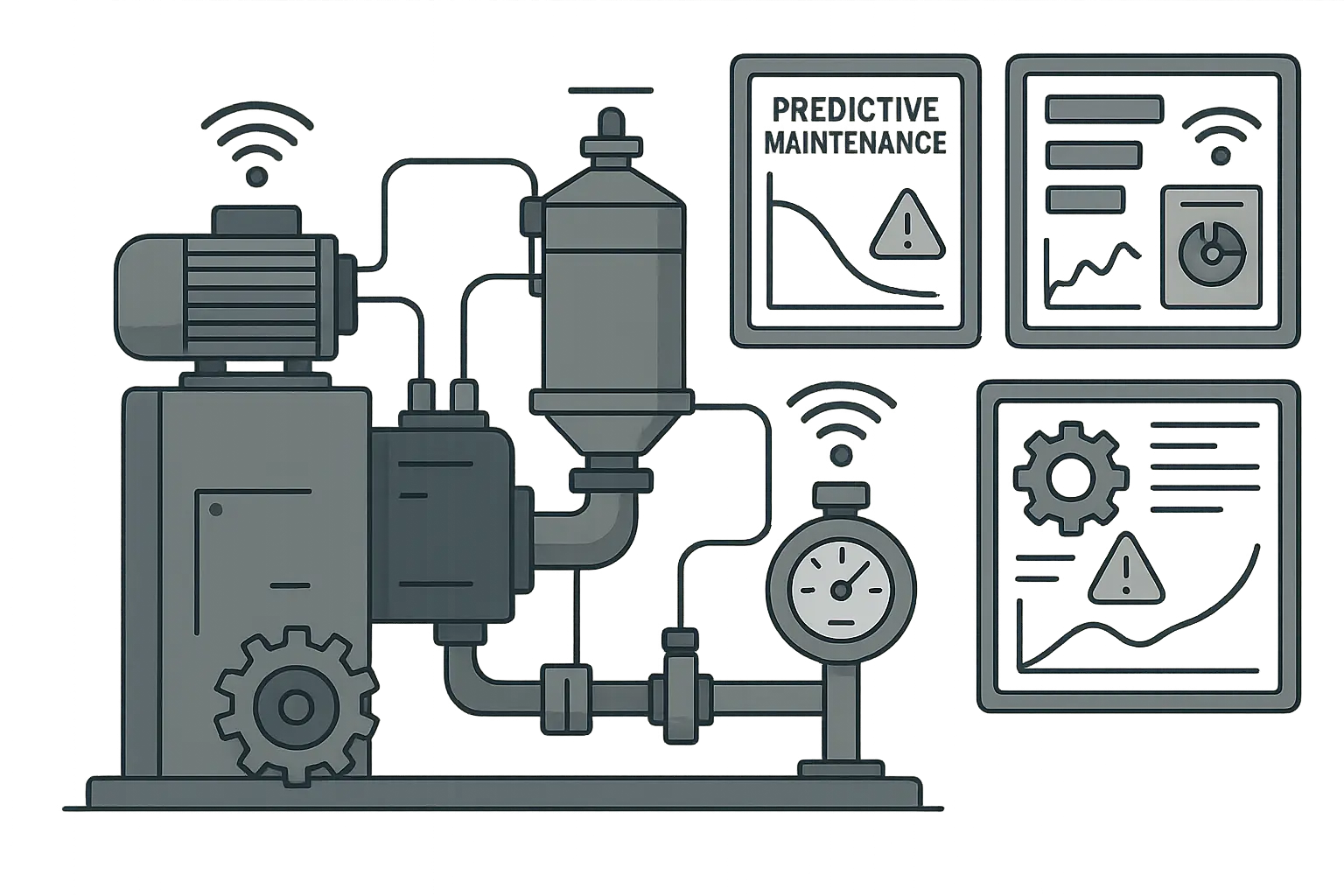

Predictive Maintenance: When Machines Tell You What They Need

Predictive maintenance represents the most mature and proven application of AI in manufacturing. Companies like GE, Siemens, and Caterpillar are demonstrating massive ROI through early failure detection, and honestly, it’s about time. We’ve been talking about “predictive maintenance” for decades, but AI has finally made it work at scale.

These five case studies show how industry leaders turned equipment monitoring from reactive firefighting into proactive optimization.

1. General Electric – Predix Platform for Jet Engine Monitoring

GE’s basically turned every jet engine into a data collection machine. Their Predix platform processes over 50 million data points per flight across 40,000+ engines globally. That’s not a typo – 50 million data points per flight. They’re tracking everything from vibration patterns to how the engine sounds when it’s cruising at 35,000 feet.

The digital twin technology creates virtual replicas of each engine, letting engineers run “what if” scenarios without actually breaking anything. This isn’t just monitoring – it’s predictive intelligence at massive scale.

Results that actually matter: 10-15% reduction in maintenance costs, 5% improvement in fuel efficiency, 99.5% engine availability rate, and here’s the big one – $2 billion in annual savings across their fleet. To put that in perspective, that’s enough to build about 20 new manufacturing plants.

2. Siemens – AI-Powered Gas Turbine Maintenance

Siemens has basically turned every turbine into a chatterbox. These 9,000+ turbines are constantly reporting back – oil pressure, vibration levels, temperature fluctuations, even tiny changes in sound patterns. It’s like having 9,000 hypochondriacs telling you exactly how they feel, which actually turns out to be incredibly useful.

Their cloud-based analytics platform processes terabytes of data daily to predict component failures up to six months in advance. Six months of advance warning transforms maintenance from emergency response to strategic planning. Imagine having half a year to source parts, schedule downtime, and coordinate with your operations team instead of scrambling when something breaks at 2 AM.

The numbers: 25% reduction in unplanned downtime, 20% increase in turbine efficiency, and $100 million in avoided maintenance costs annually.

3. Caterpillar – Autonomous Mining Equipment

Caterpillar’s self-driving mining trucks and excavators use computer vision and machine learning for autonomous operation. LiDAR and camera systems create 3D environmental maps while deep learning algorithms process visual data for obstacle detection.

The safety implications alone justify the investment. Mining’s inherently dangerous, and removing human operators from hazardous situations while maintaining (or improving) operational efficiency represents a massive win-win. Plus, these machines don’t get tired, distracted, or call in sick.

Performance gains: 15% increase in operational efficiency, 50% reduction in safety incidents, and 12% improvement in fuel consumption.

4. Rolls-Royce – IntelligentEngine Vision

Each Rolls-Royce engine contains 25,000+ sensors collecting real-time data. Let that sink in – 25,000 sensors per engine. They’re monitoring things most people don’t even know exist. This level of monitoring was impossible just a decade ago, and now it’s standard practice.

Machine learning models predict component wear patterns while digital twin technology simulates engine performance under various conditions. It’s like having a crystal ball for engine maintenance.

Bottom line results: 30% reduction in maintenance costs, 20% improvement in engine availability, and 15% increase in fuel efficiency.

5. ABB – Robotic Maintenance Systems

ABB’s taking this a step further by combining AI with robotics to actually perform predictive maintenance tasks. Computer vision systems detect equipment anomalies, machine learning algorithms predict optimal maintenance schedules, and then robotic systems perform routine maintenance tasks automatically.

This represents the next evolution – not just predicting when maintenance is needed, but actually performing that maintenance with minimal human intervention. We’re getting close to self-healing factories.

Operational impact: 40% reduction in maintenance labor costs, 25% decrease in equipment downtime, and 20% improvement in maintenance accuracy.

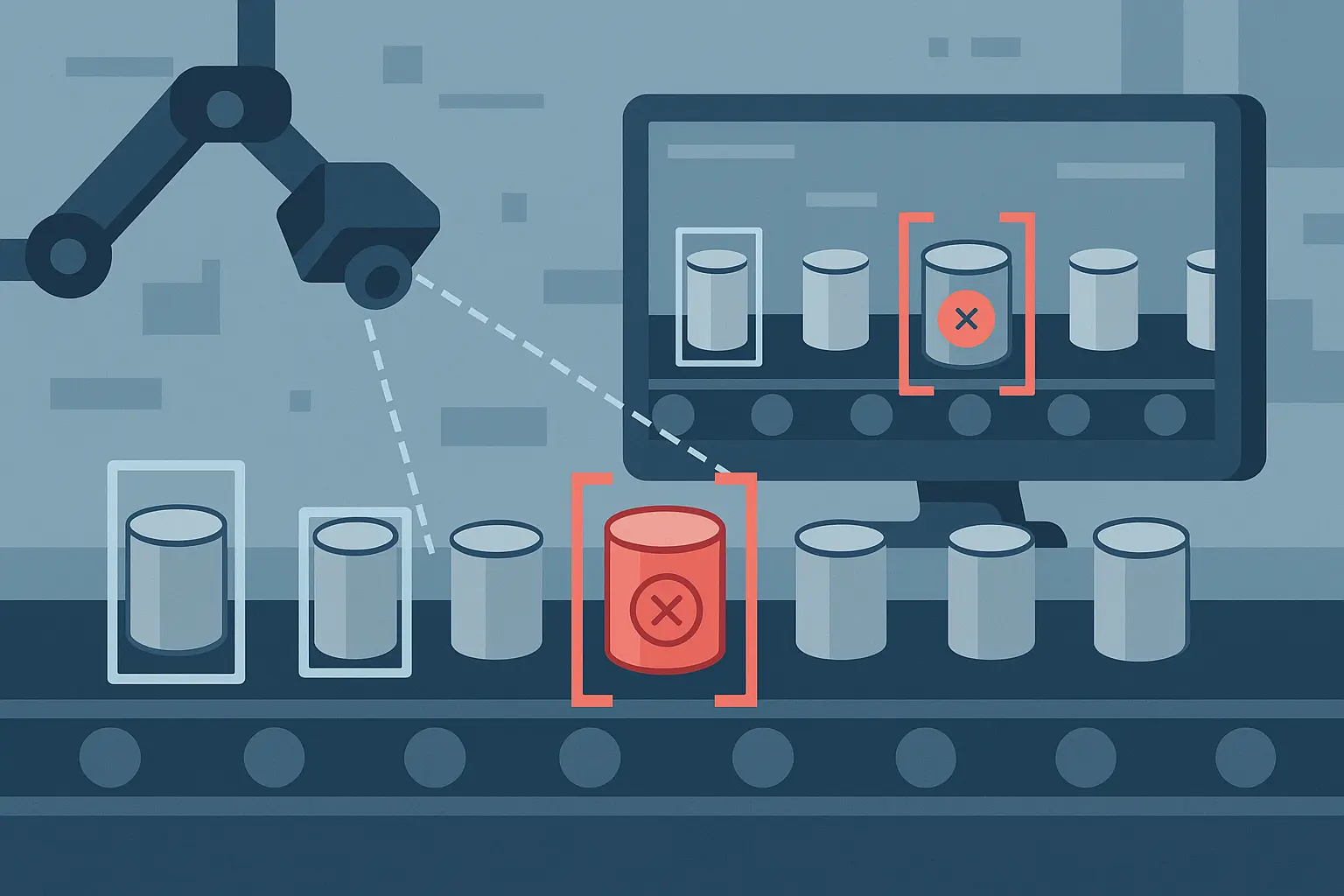

Quality Control Revolution: AI Eyes That Never Blink

Human inspectors get tired, distracted, and inconsistent. They miss things on Monday morning and Friday afternoon. AI vision systems don’t have bad days, don’t need coffee breaks, and don’t get distracted by personal problems. These five case studies demonstrate how manufacturers are achieving unprecedented quality levels through AI-powered inspection.

6. BMW – AI-Powered Visual Inspection

BMW’s computer vision systems capture 1,000+ images per vehicle, using convolutional neural networks to detect microscopic defects that human inspectors might miss. The system provides real-time feedback to production lines for immediate corrections.

Now, here’s where things get interesting. Quality control AI sounds straightforward until you realize your products don’t always look the same. Lighting changes throughout the day. Operators position parts slightly differently. What looks like a simple camera setup turns into a months-long calibration project.

BMW figured this out, though. The speed advantage is remarkable – 50% faster inspection times without sacrificing accuracy. In fact, accuracy improves dramatically with 99.7% defect detection rates.

Quality transformation: 90% reduction in defect escape rates, 50% faster inspection times, and 99.7% accuracy in defect detection.

Manufacturing companies implementing sophisticated AI systems often benefit from understanding how creating continuously learning systems AI can improve their quality control processes over time.

|

Quality Control Application |

Defect Detection Rate |

Speed Improvement |

Industry Impact |

|---|---|---|---|

|

Automotive Visual Inspection |

99.7% |

50% faster |

Warranty cost reduction |

|

Semiconductor Wafer Analysis |

95% accuracy |

70% time reduction |

Yield improvement |

|

Electronics Assembly |

90% defect reduction |

35% faster processing |

First-pass yield gains |

|

Cosmetics Quality Control |

99.8% accuracy |

30% throughput increase |

Customer satisfaction |

|

Battery Cell Inspection |

20% quality improvement |

50% time reduction |

Safety enhancement |

7. Intel – Semiconductor Wafer Inspection

Intel’s deep learning algorithms analyze scanning electron microscope images to detect defects at the nanometer scale. We’re talking about finding problems smaller than viruses. Pattern recognition algorithms identify anomalies and automatically classify defect types and severity.

Nanometer-scale detection represents the absolute cutting edge of quality control. Traditional inspection methods simply can’t operate at this level of precision. It’s like trying to spot a grain of sand on a football field from space.

Manufacturing excellence: 30% improvement in yield rates, 70% reduction in inspection time, and 95% accuracy in defect classification.

8. Foxconn – Smart Manufacturing Quality Control

Foxconn monitors 100+ assembly stations with computer vision systems. Machine learning models learn from historical defect patterns to predict and prevent quality issues before they occur.

The scale is impressive – monitoring over 100 assembly stations simultaneously while maintaining consistent quality standards across all production lines. That’s the kind of consistency that’s impossible with human inspectors alone.

Operational results: 25% reduction in defect rates, 35% improvement in first-pass yield, and 60% decrease in quality control labor costs.

9. L’Oréal – Cosmetics Quality

9. L’Oréal – Cosmetics Quality Assurance

L’Oréal uses hyperspectral imaging to capture detailed product characteristics, with machine learning algorithms detecting subtle quality variations in color consistency, packaging, and contamination.

Cosmetics quality control requires detecting variations that are barely visible to the human eye. Hyperspectral imaging captures data across multiple wavelengths, revealing defects invisible to traditional cameras. It’s like having superhuman vision that can see colors humans can’t even perceive.

Customer satisfaction gains: 40% reduction in customer complaints, 99.8% accuracy in quality assessment, and 30% increase in production throughput.

10. Tesla – Battery Cell Quality Control

Tesla combines X-ray imaging with computer vision to inspect battery cells for defects and predict performance characteristics. Machine learning models predict battery lifespan while automated systems grade and sort cells.

Battery quality directly impacts vehicle safety and performance. Tesla’s AI system ensures only the highest-quality cells make it into their vehicles, supporting their reputation for reliability. When you’re dealing with something that could potentially catch fire, you don’t mess around with quality control.

Quality assurance results: 20% improvement in battery quality, 15% increase in battery lifespan prediction accuracy, and 50% reduction in quality control time.

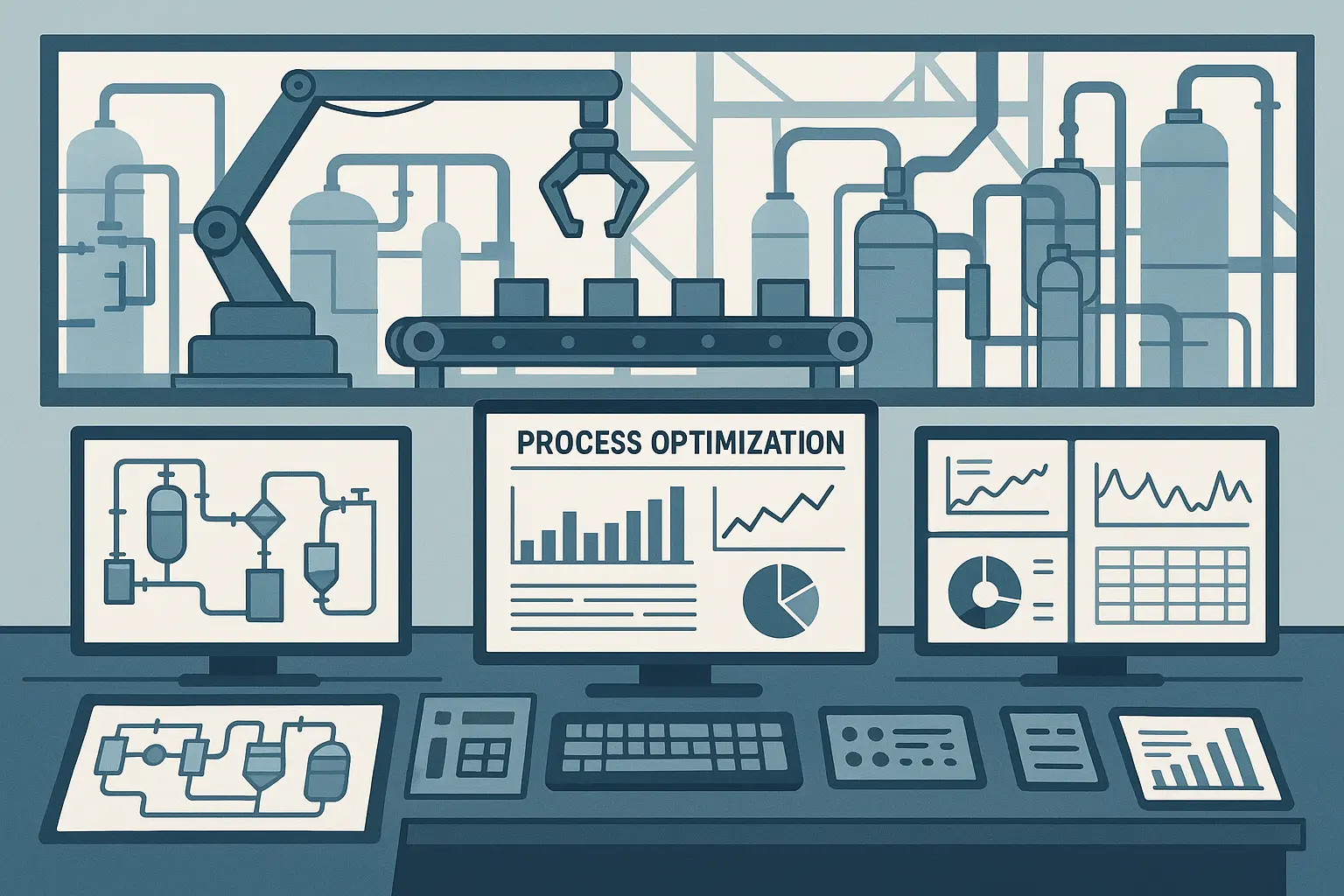

Production Optimization: The Science of Perfect Processes

Manufacturing processes involve countless variables interacting in complex ways. Temperature, pressure, timing, humidity, raw material variations – the list goes on. AI excels at finding optimal combinations that human operators might never discover, even after decades of experience.

These five case studies show how process optimization delivers measurable results that you can actually bank on.

11. ArcelorMittal – Steel Production Optimization

ArcelorMittal basically turned their steel-making process into a giant science experiment. They’re tracking everything – and I mean everything – from the exact temperature of the furnace to how humid it is outside. Their machine learning algorithms analyze 10,000+ process variables in real-time to optimize steel production parameters.

Processing 10,000 variables simultaneously would overwhelm any human operator. Hell, it would overwhelm a team of human operators. AI systems thrive in this complexity, finding optimization opportunities that would be impossible to discover manually.

Sounds like overkill until you realize they’re saving $50 million a year. Suddenly, tracking 10,000 variables doesn’t seem so crazy.

Efficiency gains: 8% reduction in energy consumption, 12% improvement in steel quality, and $50 million in annual cost savings.

A regional steel manufacturer I worked with applied ArcelorMittal’s approach on a smaller scale, monitoring 2,000 variables instead of 10,000. Their AI system identified that adjusting furnace temperature by just 15 degrees Celsius during specific production phases reduced energy consumption by 6% and improved steel consistency by 8%. The implementation cost $500,000 but generated $2.5 million in annual savings. Not bad for tweaking the thermostat.

12. Unilever – Smart Factory Operations

Unilever uses AI-driven production planning and optimization across multiple manufacturing facilities. Machine learning models optimize production schedules while real-time demand forecasting adjusts production volumes.

Coordinating production across multiple facilities requires sophisticated optimization. AI systems can balance capacity, demand, and logistics constraints in ways that manual planning simply can’t match. It’s like playing three-dimensional chess while juggling.

Operational excellence: 15% increase in overall equipment effectiveness, 20% reduction in inventory costs, and 10% improvement in on-time delivery.

13. 3M – Advanced Materials Processing

3M’s neural networks control chemical reaction parameters for advanced materials production. Real-time process monitoring and adjustment combined with predictive models optimize batch scheduling.

Chemical processes are particularly well-suited to AI optimization. Small parameter adjustments can have dramatic effects on product quality and yield, making AI’s precision invaluable. It’s like baking a cake where getting the temperature wrong by five degrees ruins the entire batch, except you’re doing it with million-dollar batches.

Process improvements: 18% reduction in material waste, 22% improvement in product consistency, and 12% increase in production yield.

14. Dow Chemical – Process Optimization

Dow Chemical uses advanced process control with machine learning to optimize complex chemical processes. Real-time optimization of reactor conditions combined with predictive maintenance for critical equipment reduces variability and improves efficiency.

Chemical manufacturing involves intricate processes where small optimizations compound into significant improvements. AI’s ability to continuously adjust parameters delivers consistent benefits that add up over time.

Chemical excellence: 10% reduction in energy costs, 15% improvement in product yield, and 25% decrease in process variability.

15. Nestlé – Food Production Optimization

Nestlé’s machine learning models control temperature, pressure, and timing in food processing. Computer vision monitors product appearance while AI-driven recipe optimization ensures consistent nutritional content.

Food manufacturing is weird for AI because everything has to be washable. Sounds obvious, but I’ve seen companies spec out amazing vision systems only to realize they can’t survive daily sanitizing cycles. Nestlé figured this out early and designed their systems accordingly.

Food production requires balancing multiple objectives – taste, nutrition, appearance, and cost. AI systems can optimize across all these dimensions simultaneously, something that’s nearly impossible for human operators to do consistently.

Food manufacturing results: 12% reduction in energy consumption, 95% consistency in product quality, and 20% improvement in production efficiency.

Supply Chain Intelligence: Moving Beyond Guesswork

Supply chains involve countless moving parts, unpredictable demand, and complex logistics challenges. Traditional approaches rely heavily on educated guesswork and historical patterns. AI brings intelligence to these systems, turning reactive management into proactive optimization.

16. Amazon – Warehouse Robotics and Inventory Optimization

Amazon deploys 200,000+ robots in fulfillment centers, using machine learning to predict demand patterns and computer vision to guide robotic picking systems. The scale of automation is unprecedented in logistics.

The combination of physical robotics and AI intelligence creates a system that operates with superhuman efficiency and accuracy. 99.99% inventory accuracy isn’t just impressive – it’s transformational for customer experience. When was the last time you ordered something from Amazon and they didn’t have it in stock?

Logistics revolution: 50% reduction in order processing time, 20% decrease in operational costs, and 99.99% inventory accuracy.

17. Walmart – Supply Chain Optimization

Walmart’s AI systems coordinate with 100,000+ suppliers, using machine learning to analyze sales data and external factors. Predictive analytics handle seasonal demand fluctuations across their massive retail network.

Managing 100,000 suppliers requires AI-level coordination. No human team could optimize across this many variables while maintaining the speed and accuracy that modern retail demands. It’s like conducting an orchestra with 100,000 musicians spread across the globe.

Supply chain mastery: 15% reduction in inventory costs, 10% improvement in product availability, and 25% decrease in supply chain disruptions.

18. Maersk – Smart Container Logistics

Maersk’s machine learning algorithms analyze weather, port congestion, and fuel costs to optimize container shipping routes and schedules. AI optimizes vessel routing while predictive maintenance keeps containers operational.

Global shipping involves countless variables – weather patterns, port congestion, fuel prices, and geopolitical factors. AI systems can process all these inputs to find optimal routing solutions that would take human planners weeks to calculate.

Shipping optimization: 12% reduction in shipping costs, 20% improvement in on-time delivery, and 15% decrease in fuel consumption.

19. DHL – Predictive Logistics

DHL uses machine learning models to forecast shipping volumes and optimize last-mile delivery routes in real-time. Predictive analytics support capacity planning across their global network.

Last-mile delivery represents the most complex and expensive part of logistics. AI optimization can find routing efficiencies that dramatically reduce costs while improving service levels. It’s the difference between a delivery driver wandering around neighborhoods randomly versus having a perfectly optimized route.

Delivery excellence: 18% improvement in delivery efficiency, 25% reduction in transportation costs, and 95% on-time delivery rate.

A regional logistics company serving 500 manufacturing clients implemented DHL’s predictive routing approach on a smaller scale. By analyzing delivery patterns, traffic data, and customer preferences, their AI system reduced average delivery times by 22% and cut fuel costs by 18%. The key insight: customers preferred consistent delivery windows over fastest possible delivery, allowing the AI to optimize routes for efficiency rather than pure speed.

Human-Robot Collaboration: Safety Meets Productivity

The future of manufacturing isn’t humans versus robots – it’s humans working alongside intelligent machines. AI enables safe, productive collaboration where both humans and robots contribute their unique strengths.

These three case studies show how this collaboration is transforming manufacturing floors across industries.

20. Ford – Collaborative Robotics

Ford’s AI-powered collaborative robots work alongside human workers using computer vision systems to monitor human-robot interactions. Machine learning adapts robot behavior to human presence while AI coordinates complex assembly tasks.

I remember visiting a Ford plant where they’d just installed collaborative robots. The old-timers were convinced the robots would either hurt someone or slow everything down. Six months later, the same guys were bragging about how their injury rate dropped to almost zero while their productivity went through the roof.

Collaborative success: 60% reduction in workplace injuries, 25% increase in assembly line productivity, and 40% improvement in worker satisfaction.

21. Mercedes-Benz – Smart Factory Safety

Mercedes-Benz uses computer vision to monitor factory floors for safety hazards and coordinate human-robot collaboration. AI predicts potential safety incidents while real-time alerts and emergency response systems prevent accidents.

Predicting safety incidents before they happen represents a fundamental shift from reactive to proactive safety management. The 99.5% safety compliance rate demonstrates the effectiveness of AI-powered monitoring.

Here’s where things get tricky with collaborative robotics: you’ll start getting alerts about near-misses that didn’t actually result in accidents. Your safety team might push back, saying “nothing happened, why are we worried?” Trust me, this conversation happens at every plant.

Safety transformation: 70% reduction in safety incidents, 99.5% safety compliance rate, and 30% improvement in operational efficiency.

22. KUKA – Intelligent Automation

KUKA’s AI enables robots to adapt to changing production requirements and work safely with humans. Machine learning allows robots to learn new tasks while computer vision enables safe human-robot interaction.

The flexibility advantage is crucial – 45% increase in production flexibility means manufacturers can adapt quickly to changing market demands without major retooling. That’s the difference between thriving and struggling when customer requirements shift.

Adaptive manufacturing: 45% increase in production flexibility, 35% reduction in programming time, and 50% improvement in worker safety.

Energy Management: The Green AI Revolution

Energy costs and environmental impact are becoming critical competitive factors. Smart manufacturers are discovering that AI transforms energy management from cost center to competitive advantage.

These three case studies demonstrate how AI delivers both environmental and financial benefits.

23. Google – Data Center Energy Optimization

Google’s DeepMind AI system optimizes data center cooling and energy consumption by analyzing thousands of sensors and controlling cooling systems in real-time. Neural networks predict optimal energy usage patterns across their global infrastructure.

The 40% reduction in cooling energy consumption translates to over $100 million in annual savings. This isn’t just environmental responsibility – it’s smart business. When you’re operating at Google’s scale, every percentage point of efficiency improvement adds up to serious money.

Energy excellence: 40% reduction in cooling energy consumption, 15% decrease in total energy usage, and $100+ million in annual energy savings.

24. BASF – Chemical Plant Energy Management

BASF uses machine learning models to optimize steam and power generation across chemical production facilities. AI coordinates energy usage across multiple production units while predictive analytics support renewable energy integration.

Chemical manufacturing is energy-intensive, making optimization particularly valuable. The €50 million annual savings demonstrate the financial impact of intelligent energy management. That’s not pocket change – that’s transformational for bottom-line performance.

Sustainable manufacturing: 20% reduction in energy consumption, 25% decrease in CO2 emissions, and €50 million annual energy cost savings.

25. Interface Inc. – Carbon Negative Manufacturing

Interface Inc. uses AI to optimize manufacturing processes for carbon-negative production while maintaining quality. Machine learning optimizes material usage and waste reduction while AI coordinates renewable energy usage.

Achieving carbon-negative manufacturing while maintaining quality and profitability represents the ultimate sustainability challenge. Interface proves it’s possible with intelligent AI implementation. They’re not just reducing their environmental impact – they’re actually improving it beyond neutral.

Environmental leadership: 96% reduction in carbon intensity, carbon-negative manufacturing achieved, and 20% reduction in material waste.

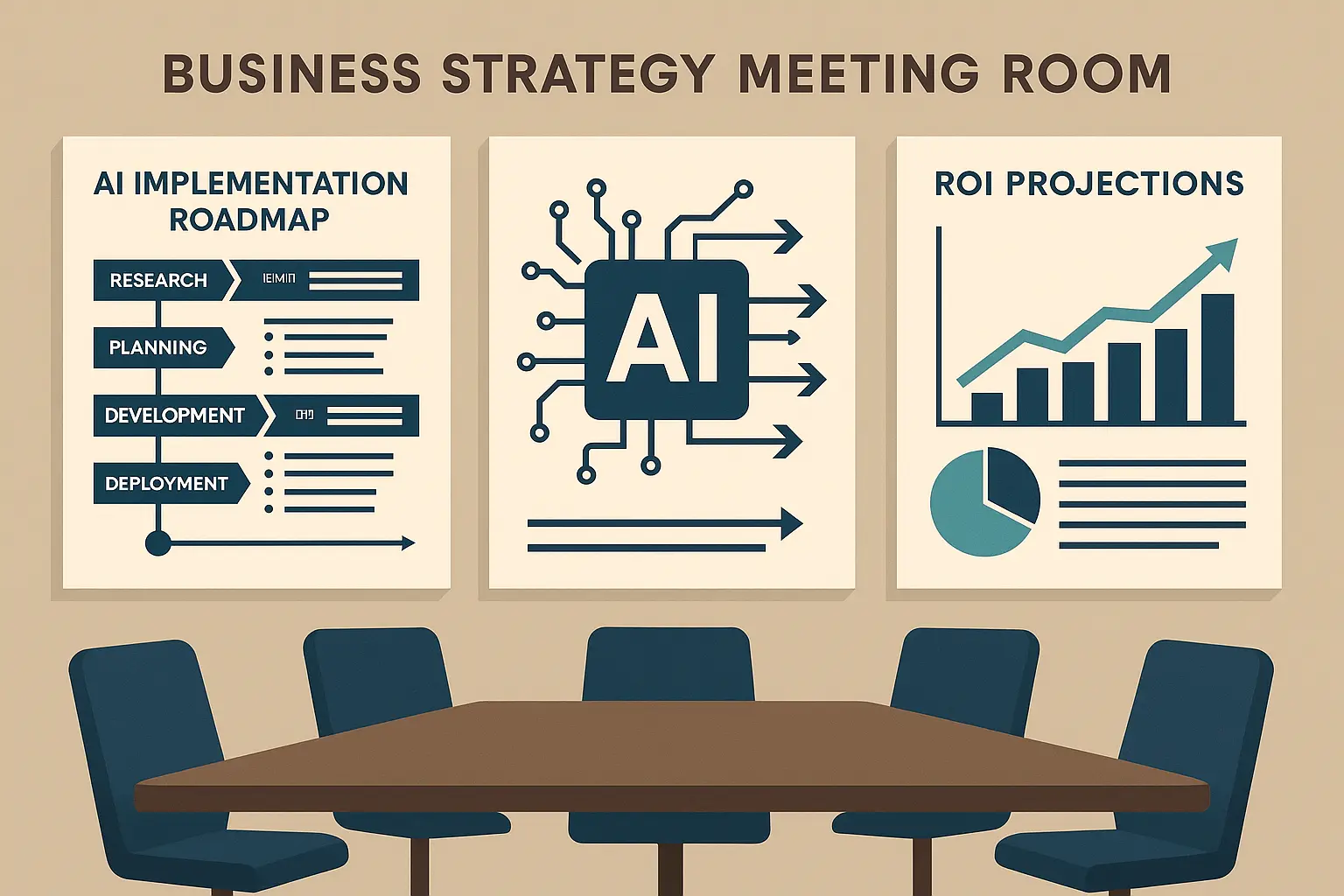

How to Evaluate These Case Studies for Your Business

These 25 case studies offer a roadmap, but your path will be unique. Here’s how to evaluate which approaches make sense for your specific situation without getting caught up in the hype.

When evaluating complex AI implementations, manufacturers should consider using specialized ROI calculator tools to accurately assess the financial impact of their technology investments.

|

Implementation Type |

ROI Timeline |

Complexity Level |

Success Factors |

Risk Assessment |

|

|---|---|---|---|---|---|

|

Predictive Maintenance |

12-18 months |

Medium |

Existing sensors, data infrastructure |

Medium risk, high reward |

|

|

Quality Control AI |

6-12 months |

Low-Medium |

Camera systems, product consistency |

Low risk, fast payback |

|

|

Process Optimization |

18-30 months |

High |

Complex data integration |

High complexity, transformational impact |

|

|

Supply Chain |

Supply Chain AI |

12-24 months |

Medium-High |

ERP integration, supplier cooperation |

Medium risk, scalable benefits |

|

Energy Management |

6-18 months |

Low-Medium |

Utility data access, IoT sensors |

Low risk, immediate savings |

ROI Reality Check

Look, here’s how I tell clients to think about ROI: if you’re not seeing some kind of improvement in the first six months, something’s wrong. Maybe not full payback, but you should see the system actually working. If you’re still “fine-tuning” after a year, you probably picked the wrong solution.

The highest-ROI cases consistently focus on predictive maintenance and quality control. GE’s $2 billion savings and BMW’s 90% defect reduction represent the gold standard, but your results will depend on your specific circumstances.

Performance improvements vary widely by industry and application. Automotive manufacturers see excellent results from quality control AI, while heavy industry benefits most from predictive maintenance applications.

Technical Feasibility Assessment

High-feasibility implementations work with existing infrastructure. BMW’s visual inspection and Amazon’s warehouse robotics succeed partly because they build on established systems rather than requiring complete overhauls.

Medium-feasibility projects like GE’s Predix platform require significant infrastructure investment but offer proven technology with strong vendor support. Complex implementations like Caterpillar’s autonomous equipment offer transformational benefits but carry higher risks and require extensive change management.

Implementation Complexity Considerations

Low-complexity projects focus on software solutions that integrate with existing systems. L’Oréal’s quality assurance and DHL’s predictive logistics fall into this category – relatively straightforward implementations with quick wins.

Medium-complexity implementations require data infrastructure development and cross-functional coordination. Siemens’ gas turbine maintenance and Unilever’s smart factory operations represent this middle ground.

High-complexity projects involve safety-critical systems or comprehensive operational changes. Caterpillar’s autonomous equipment and Mercedes-Benz’s smart factory safety require extensive planning and gradual rollouts. Don’t try to boil the ocean on day one.

Strategic Alignment Framework

Immediate competitive advantage comes from quality control and operational efficiency improvements. BMW’s visual inspection and Amazon’s warehouse robotics deliver quick wins that competitors struggle to match.

Long-term strategic value emerges from transformational applications like GE’s service platform evolution and Interface’s sustainability leadership.

Operational excellence focus suits manufacturers prioritizing cost reduction and efficiency gains through applications like ArcelorMittal’s steel optimization and Google’s energy management.

Manufacturing executives often benefit from understanding comprehensive market sizing guide business opportunity analysis when evaluating AI implementation potential across different production lines.

Why The Marketing Agency Matters for AI-Forward Manufacturers

Your AI implementation success story deserves an audience that understands its value. Manufacturing companies investing millions in AI transformation often struggle to communicate these innovations effectively to customers, investors, and industry stakeholders.

The Marketing Agency applies the same data-driven, scientific approach that makes AI manufacturing implementations successful. Just as GE’s Predix platform processes 50 million data points per flight, our proprietary systems analyze campaign data in real-time, optimizing ad spend and targeting parameters for maximum ROI.

We understand the technical complexity behind your AI achievements because we use similar methodologies in our marketing optimization. When you’ve reduced defects by 90% or achieved $50 million in annual savings, you need marketing partners who can translate those technical wins into compelling business narratives.

Our expertise in generative engine optimization ensures your AI innovation stories reach decision-makers through emerging discovery channels, positioning your manufacturing advances where they’ll have maximum impact.

Our LLM Optimization ensures your artificial intelligence in manufacturing stories reach the right audiences through emerging discovery channels. As large language models become primary research tools for B2B buyers, we position your manufacturing advances where decision-makers will find them.

Ready to turn your AI manufacturing success into market leadership? We can discuss how data-driven marketing can amplify your technological investments.

Final Thoughts

These 25 case studies prove AI in manufacturing has moved far beyond experimental pilots. We’re seeing billion-dollar savings, dramatic quality improvements, and fundamental transformations in how products get made.

The patterns are clear: predictive maintenance delivers the highest absolute ROI, quality control provides the fastest payback, and process optimization offers the most consistent results across industries. But success isn’t guaranteed just because the technology works.

The manufacturers winning with AI share common approaches. They start with specific problems rather than broad transformations. They invest in data infrastructure before deploying algorithms. Most importantly, they keep humans in the loop, treating AI as augmentation rather than replacement.

Your manufacturing AI journey doesn’t have to mirror these exact implementations, but the principles behind their success are universal. Focus on measurable problems, choose proven technologies over cutting-edge experiments, and plan for organizational change as much as technical implementation.

Start small, prove it works, then scale up. Don’t try to boil the ocean on day one. The fourth industrial revolution isn’t coming – it’s here. These 25 examples show the way forward for manufacturers ready to embrace intelligent automation while maintaining the human expertise that drives real innovation.