Last week I was digging through some industry data when I stumbled across a stat that stopped me cold. Turns out, according to Meteor Space’s 2024 warehouse automation analysis, 80% of warehouses are still running on manual processes that are basically error magnets. This hit me hard because just six months ago, I watched workers at a client’s facility literally running between aisles with clipboards, trying to keep up with orders. It was like watching a really expensive game of tag.

Here’s the reality – while e-commerce keeps exploding and supply chains get crazier by the day, most warehouses are stuck in the stone age. But here’s the thing that really surprised me: the 20% that have embraced automation aren’t just doing better – they’re absolutely crushing it. We’re talking 50% faster fulfillment, 99.99% accuracy rates, and ROI numbers that make CFOs do happy dances.

I’ve spent the last few months diving deep into real-world automation implementations, and what I found will probably surprise you. Some of the most successful projects weren’t the flashiest or most expensive – they were the ones that solved specific problems with surgical precision.

Table of Contents

-

What to Look for When Evaluating Warehouse Automation Case Studies

-

25 Real-World Warehouse Automation Success Stories

-

Robotic Systems and Autonomous Mobile Robots (AMRs)

-

Automated Storage and Retrieval Systems (AS/RS)

-

Conveyor and Sortation Systems

-

Artificial Intelligence and Machine Learning Systems

-

Voice Technology and Wearable Systems

-

Vision Systems and Quality Control

-

-

How These Case Studies Stack Up: Performance Analysis

-

Risk Assessment: What Could Go Wrong

-

How The Marketing Agency Helps Automation Companies Scale

-

Final Thoughts

TL;DR

-

Amazon’s Kiva robot fleet processes orders 50% faster with 99.99% accuracy across 200,000+ robots

-

Walmart’s Alphabot system achieves 10x faster order picking in just 20,000 square feet

-

Voice technology implementations offer the fastest ROI at 12-24 months with immediate productivity gains

-

AI-powered systems like Ocado’s platform can handle 50,000 orders per week with 95% space utilization

-

Full facility automation requires 18+ months but delivers transformational results

-

Collaborative robots provide the sweet spot of moderate investment with quick integration

-

Vision systems achieve 99.95% defect detection accuracy, 10x faster than human inspection

What to Look for When Evaluating Warehouse Automation Case Studies

When you’re looking at automation case studies, there are a few things I always check first. It’s easy to get overwhelmed by all the technical jargon and impressive-sounding numbers, but I’ve learned the devil’s in the details. Much like our approach to analyzing B2B case studies for marketing success, you need a systematic way to cut through the marketing fluff and find what really matters.

Financial Reality Check

The first thing I look for isn’t those flashy productivity numbers – it’s the honest financial picture. Look, I get it – dropping millions on robots sounds terrifying. ROI timelines typically range from 18 months to 5 years, but here’s what most case studies won’t tell you upfront: the hidden costs can absolutely kill your project.

Total cost of ownership goes way beyond that sticker price. You’ve got integration fees (which can be brutal), downtime during implementation, ongoing maintenance contracts, and training costs that add up quickly. I’ve been in meetings where CFOs nearly choked on their coffee – companies budget $2 million for a system only to discover they need another $800K for proper integration and staff training.

|

Automation Type |

Initial Investment |

Hidden Costs |

Total ROI Timeline |

|---|---|---|---|

|

Voice Technology |

$50K-$200K |

Training (20%), Integration (15%) |

12-24 months |

|

Collaborative Robots |

$200K-$800K |

Safety Systems (25%), Programming (20%) |

18-36 months |

|

AS/RS Systems |

$1M-$5M |

Infrastructure (30%), Downtime (15%) |

24-48 months |

|

Full Robotic Facility |

$10M-$50M |

Redesign (40%), Training (25%) |

36-60 months |

Scalability economics matter more than you might think. How do costs change when you need to handle Black Friday volumes versus slow January periods? The best case studies show you both scenarios – not just the pretty peak numbers.

Operational Performance That Actually Matters

Throughput improvements sound great on paper, but dig deeper. What were they comparing against? Was the warehouse already optimized, or were they starting from complete chaos?

Here’s a real example that puts this in perspective: a mid-sized e-commerce company processing 5,000 orders daily with manual picking. Their baseline accuracy was 97%, with workers walking an average of 12 miles per shift – basically a half marathon every day. After implementing voice-directed picking, they hit 99.5% accuracy and cut walking by 40%. But here’s the catch – a pharmaceutical distributor starting with 99.8% accuracy would see totally different results from the same tech.

Accuracy rates need context too. A 99.9% accuracy rate means different things for a pharmaceutical distributor versus a clothing retailer. One mistake with controlled substances could shut you down – one wrong t-shirt size just annoys a customer.

Space utilization often gets overlooked, but it’s crucial. If your lease is up for renewal, an automation system that doubles your effective capacity might be worth more than the productivity gains alone.

Technical Compatibility: The Make-or-Break Factor

This is where I see most projects crash and burn. Your shiny new automation system needs to play nice with your existing WMS, ERP, and whatever other systems you’ve got running. Integration complexity varies wildly – some solutions plug right in, others require months of custom development that’ll make your IT team want to quit.

Flexibility matters more in today’s crazy market. Can the system adapt to new product lines? Seasonal demand spikes? Supply chain disruptions? The most successful implementations I’ve studied prioritize adaptability over raw speed.

Implementation Realities

Those deployment timelines in case studies are often… let’s call them optimistic. Add 20-30% to whatever timeline you see, especially for complex systems. Business disruption during transition is real – plan for it or it’ll plan for you.

Training requirements get underestimated constantly. Your team needs to operate the new system, troubleshoot it, maintain it, and optimize it over time. One operations manager told me their biggest mistake was thinking they could wing the training part.

25 Real-World Warehouse Automation Success Stories

These 25 case studies span six major categories of warehouse automation, from Amazon’s massive robot deployments to specialized vision systems. I’ve dug into the real numbers, talked to people who’ve lived through these implementations, and tried to give you the unvarnished truth about what actually works.

Robotic Systems and Autonomous Mobile Robots (AMRs)

1. Amazon’s Kiva Robot Fleet: The Gold Standard

Amazon’s Kiva system isn’t just impressive – it’s completely bonkers. With 200,000+ robots across 175+ fulfillment centers, they’ve basically reimagined how warehouses work. That’s like having a robot army the size of a small city.

These orange robots lift entire inventory pods (up to 3,000 pounds each) and haul them to human workers at picking stations. Navigation happens through QR codes on warehouse floors – basically like a GPS system painted on the ground, with smart software that makes sure the robots don’t crash into each other.

The results speak for themselves: 50% reduction in order fulfillment time, 20% increase in storage density, 40% reduction in operating costs, and 99.99% inventory accuracy. But here’s the catch – this required complete warehouse redesigns, 18-month implementation timelines per facility, and $15-20 million investments per location. Not exactly pocket change.

2. Walmart’s Alphabot Micro-Fulfillment Revolution

Walmart took a totally different approach with their Alphabot system, creating micro-fulfillment centers within existing stores. This handles online grocery orders with robots retrieving items from compact storage areas and delivering them to human associates.

In just 20,000 square feet – about the size of a grocery store – they’re storing 20,000 SKUs with 85% space utilization efficiency. The robots operate on a three-dimensional grid system (think giant 3D chess board) with temperature-controlled zones for different product types. Results include 10x faster order picking, 99.5% order accuracy, and 4-hour order fulfillment capability.

3. DHL’s Collaborative Robots (LocusBots)

DHL’s approach focuses on collaboration rather than replacement. Their LocusBots guide workers to optimal picking paths while carrying items, reducing walking time by 50% and achieving 40% productivity increases in pharmaceutical distribution centers. What I love about this is it makes workers more efficient instead of replacing them entirely.

4. FedEx Ground Automated Sort System

FedEx’s high-speed sortation robots process 50,000 packages per hour with 99.5% accuracy. That’s basically one package every second, all day long. They’ve reduced manual sorting labor by 35% while handling 3x package volume growth – crucial for their business model.

5. Shopify’s 6 River Systems ChuckBots

Shopify Fulfillment Network deployed collaborative mobile robots that learn warehouse layouts and optimize routes automatically. They’re seeing 2-3x productivity improvements in order picking with a 6-month payback period. The speed of that ROI is pretty remarkable.

Automated Storage and Retrieval Systems (AS/RS)

6. Zara’s Automated Distribution Center: Fast Fashion at Scale

Zara’s 1.2 million square foot facility in Spain handles their fast-fashion model with unprecedented speed. The automated hanging garment system can store 400,000 hanging garments with RFID integration for real-time tracking.

Zara dropped €200 million over three years on this thing, but the results are insane: 24-hour global distribution capability, 99.8% order accuracy, 60% reduction in labor costs, and 200% increase in processing capacity. The system integrates with 2,000+ retail locations worldwide.

Similar to how our retail website migration case study demonstrates transformation challenges, Zara’s implementation required careful coordination across multiple systems and locations.

Here’s what’s really interesting – a regional clothing retailer with 50 stores saw Zara’s success and implemented a scaled-down version in their 100,000 square foot distribution center. Their investment was only $8 million, but they achieved similar percentage improvements: 55% reduction in labor costs, 180% increase in processing capacity, and most importantly, reduced their season changeover time from 6 weeks to 10 days. That’s the kind of competitive advantage that can make or break a retail business.

7. Home Depot’s Rapid Deployment Center

Home Depot’s 170,000 square foot automated facility combines AS/RS with robotic picking and packing. The system handles 100,000 SKUs with robotic arms using vision systems for item identification and automated packaging with right-sizing capability.

Results include same-day delivery capability for 90% of metropolitan areas, 45% reduction in fulfillment costs, 99.7% order accuracy, and 300% increase in throughput capacity. Now they can get stuff to customers same-day, which is pretty incredible for hardware.

8. IKEA’s Automated Small Parts Warehouse

IKEA’s cube-based automated storage system achieves 85% space utilization improvement and 50% faster order fulfillment for small items. They’re handling 40,000 SKUs in space previously used for just 15,000. When you’re dealing with Swedish furniture parts, that kind of efficiency matters.

9. Sysco’s Cold Storage Automation

Sysco’s automated cold storage AS/RS operates in temperatures ranging from -20°F to 35°F, achieving 30% energy savings and 99.9% inventory accuracy despite challenging temperature conditions. Working in those temperatures is brutal for humans, so automation makes perfect sense here.

10. McKesson’s Pharmaceutical AS/RS

McKesson’s high-density pharmaceutical storage maintains FDA compliance while achieving 99.99% accuracy for controlled substances and 40% reduction in picking errors. When you’re dealing with medications, that accuracy isn’t just nice to have – it’s literally life or death.

Conveyor and Sortation Systems

11. UPS Worldport Automated Sort Facility: Logistics at Scale

UPS Worldport’s 5.2 million square foot facility represents one of the world’s largest automated sorting operations. With 155 miles of conveyor belts processing 416,000 packages per hour, they achieve 99.9% sorting accuracy while handling 2 million packages daily.

The first time I saw footage of this place in action, my jaw literally dropped. The facility operates 24/7 with RFID and barcode scanning integration, automated loading and unloading systems, and global tracking integration. This has reduced delivery times globally, improved fuel efficiency by 30% through optimized routing, and scales to handle 300% volume increases during peak seasons.

12. Target’s Sortation Centers: Omnichannel Excellence

Target’s sortation centers bridge distribution centers and stores using cross-belt sortation technology. With 30,000 packages per hour capacity and real-time routing optimization, they’ve achieved 2-day delivery to 80% of the US population.

The system delivers 25% reduction in shipping costs, 95% same-day fulfillment for store pickup orders, and 40% improvement in inventory turnover. What’s clever is how they’re using stores as mini distribution centers.

13. Macy’s Automated Fulfillment Network

Macy’s tilt-tray sortation systems handle 100,000 items per day with 99.5% accuracy rates. The system enables ship-from-store capabilities for 500+ locations with 35% faster order processing. Turning every store into a fulfillment center is pretty brilliant.

14. Best Buy’s Micro-Fulfillment Sortation

Best Buy installed compact automated sortation in 250+ stores, handling online orders alongside in-store pickup with 60% reduction in order preparation time. When you need that graphics card today, this is how they make it happen.

15. Costco’s Cross-Dock Automation

Costco’s automated cross-docking systems ensure 90% of products bypass traditional storage, enabling 24-hour supplier-to-store delivery with 20% reduction in handling costs. Their whole model depends on fast inventory turnover, so this automation is crucial.

Artificial Intelligence and Machine Learning Systems

16. Ocado’s AI-Powered Fulfillment Platform: The Future of Grocery

Ocado’s Customer Fulfillment Centers represent the pinnacle of AI-driven warehouse automation. With 1,000+ robots per facility operating on grid systems, AI algorithms optimize robot paths and collision avoidance while machine learning predicts customer demand and inventory placement.

The results are absolutely staggering: 99.9% order accuracy, 50,000 orders per week per facility, 3.5-minute average order picking time, and 95% space utilization efficiency. Their AI handles predictive analytics for inventory positioning, real-time route optimization, demand forecasting with 95% accuracy, and automated quality inspection using computer vision.

17. Alibaba’s Smart Warehouse Network: AI at National Scale

Alibaba’s Cainiao network uses AI to coordinate 500+ automated warehouses across China. Machine learning algorithms process 1 billion logistics data points daily – that’s an insane amount of data – enabling automated inventory placement based on purchase predictions and AI-powered demand forecasting with regional customization.

This massive network delivers 24-hour delivery to 70% of China, 40% reduction in inventory holding costs, 99.7% order accuracy across the network, and 60% improvement in space utilization.

18. JD.com’s Unmanned Warehouse

JD.com operates fully automated warehouses with zero human workers during operation. AI manages 200,000 orders daily with 99.99% accuracy rates, with machine learning optimizing all processes continuously. It’s like something out of a sci-fi movie, but it’s happening right now.

19. Kroger’s AI Inventory Management

Kroger’s AI-powered demand prediction system achieves 15% reduction in out-of-stock situations. Predictive analytics handle 60,000+ SKUs with automated reordering based on weather patterns and local events. When a storm’s coming, the AI already knows to stock up on bread and milk.

20. Nike’s AI-Driven Distribution

Nike’s machine learning system delivers 30% improvement in demand forecast accuracy, AI-powered size run optimization, and seasonal trend prediction with 90% accuracy. Predicting what sneakers will be hot next season is basically printing money.

Voice Technology and Wearable Systems

21. Honeywell’s Voice-Directed Warehousing

Honeywell’s voice picking and task management systems deliver 25% productivity improvements with 99.9% accuracy rates. The hands-free operation reduces training time for new workers by 35%. No more fumbling with scanners or clipboards.

22. ProGlove Smart Gloves at BMW Logistics

BMW’s implementation of ProGlove wearable barcode scanning achieves 15% faster scanning speeds with ergonomic improvements that reduce repetitive strain. Each scan is 4 seconds faster and fully integrated with WMS systems. Those seconds add up over thousands of scans per day.

23. Zebra Technologies Wearable Computers at DHL

DHL’s wrist-mounted mobile computers enable hands-free scanning and data entry, delivering 20% productivity increases with real-time inventory updates and voice command integration.

Here’s a real-world example that shows how this works: a food distributor with 200 warehouse workers was bleeding money on turnover and training costs. They implemented voice-directed picking across their 500,000 square foot facility. New employees now reach full productivity in 3 days instead of 2 weeks, reducing training costs by 70%. The voice system works in 12 languages, accommodating their diverse workforce, and achieved 99.8% accuracy rates while reducing workers’ daily walking distance by 35%. That’s the kind of win-win that makes everyone happy.

Vision Systems and Quality Control

24. Cognex Vision Systems: AI-Powered Quality Control

Advanced vision systems using AI perform quality control inspections that blow human capabilities out of the water. High-resolution cameras with AI image processing provide real-time defect detection and classification, with machine learning algorithms that improve over time.

Results include 99.95% defect detection accuracy, 10x faster inspection speeds compared to humans, 90% reduction in quality-related returns, and consistent quality standards across multiple shifts. Applications span pharmaceutical tablet inspection, food packaging verification, electronics component placement, and textile quality assessment.

25. Sick Sensor Intelligence Automated Inspection

Automotive parts manufacturers use laser-based dimensional inspection for 100% parts inspection at production speed with 0.1mm accuracy, automated rejection of defective parts, and full integration with manufacturing execution systems.

How These Case Studies Stack Up: Performance Analysis

Looking at these 25 case studies, some clear patterns emerge that can help you figure out what might work for your operation. The ROI picture varies dramatically depending on your approach, and honestly, some of these results surprised even me.

Financial Performance Breakdown

Voice technology systems and collaborative robots are crushing it with 12-24 month payback periods. These solutions don’t require massive upfront investments and integrate quickly with existing operations. Before you start panicking about the costs, these are your safest bets.

Medium ROI solutions (24-36 months) include AS/RS systems and sortation systems. While they require higher upfront investments, the operational savings compound over time. Vision systems fall into this category too, with quality cost savings offsetting moderate investments.

Long-term ROI projects (36+ months) involve full robotic facilities and complex AI platforms. Amazon’s Kiva system and Ocado’s AI platform require massive transformations and complete redesigns, but the results justify the investment for high-volume operations.

|

Performance Metric |

Top Performers |

Average Results |

Implementation Complexity |

|---|---|---|---|

|

Accuracy Rate |

JD.com (99.99%), Amazon Kiva (99.99%) |

99.5% |

High – Full automation |

|

Throughput Improvement |

Walmart Alphabot (10x), UPS Worldport (416K/hr) |

2-3x |

Medium to High |

|

Space Utilization |

Ocado (95%), Walmart (85%) |

60-70% |

High – Grid systems |

|

ROI Timeline |

Voice Tech (12-24 mo), Collaborative Robots (18-36 mo) |

24-48 months |

Low to Medium |

Operational Performance Champions

Amazon’s Kiva system leads throughput improvements with 50% reduction in fulfillment time. Ocado’s AI platform follows closely with 3.5-minute average order picking, while UPS Worldport processes an incredible 416,000 packages per hour.

Accuracy rates tell an interesting story. JD.com’s unmanned warehouse and Amazon’s Kiva system both achieve 99.99% accuracy, while Cognex vision systems hit 99.95% defect detection. I always get suspicious when I see 99.99% accuracy claims, but these numbers are legit and business-critical for industries where errors cost serious money.

Space utilization leaders include Ocado at 95%, Walmart’s Alphabot at 85%, and IKEA’s cube storage with 85% improvement. In expensive real estate markets, these efficiency gains can justify automation investments on their own.

Technical Integration Reality

Voice systems and wearable technology offer the easiest integration paths. They work with existing WMS systems and require minimal infrastructure changes. Collaborative robots and basic AI software solutions fall into the moderate complexity category – they need WMS integration but use proven methodologies.

The most complex integrations involve full robotic systems, AI platforms, and large-scale conveyor networks. These require complete system redesigns, custom development, and extensive testing periods that can stretch implementations beyond 18 months.

Implementation Timeline Realities

Quick deployment options (3-6 months) include voice technology, wearable systems, basic AI software, and vision inspection systems. These solutions can often be piloted in small areas before full rollouts.

Medium deployment projects (6-18 months) cover collaborative robots, micro-fulfillment centers, sortation upgrades, and AS/RS implementations. These require more planning but follow established methodologies.

Extended deployments (18+ months) involve complete facility automation, large-scale conveyor networks, custom AI development, and full warehouse redesigns. The complexity is enormous, but so are the potential rewards.

Industry-Specific Success Patterns

E-commerce and retail operations gravitate toward high-volume, varied SKU solutions. Cases from Amazon, Walmart, Zara, and Target prove their worth in environments demanding speed and flexibility with diverse product mixes.

Manufacturing and industrial applications focus on precision and quality control. The pharmaceutical and automotive examples show how specialized handling, regulatory compliance, and quality requirements drive technology choices.

Food and pharmaceutical industries prioritize temperature control, regulatory compliance, and traceability. Sysco’s cold storage and McKesson’s pharmaceutical systems demonstrate how industry-specific requirements shape automation decisions.

3PL and logistics providers need flexible, multi-client capable systems. DHL, UPS, and FedEx examples show how scalability and adaptability matter more than raw performance in these environments.

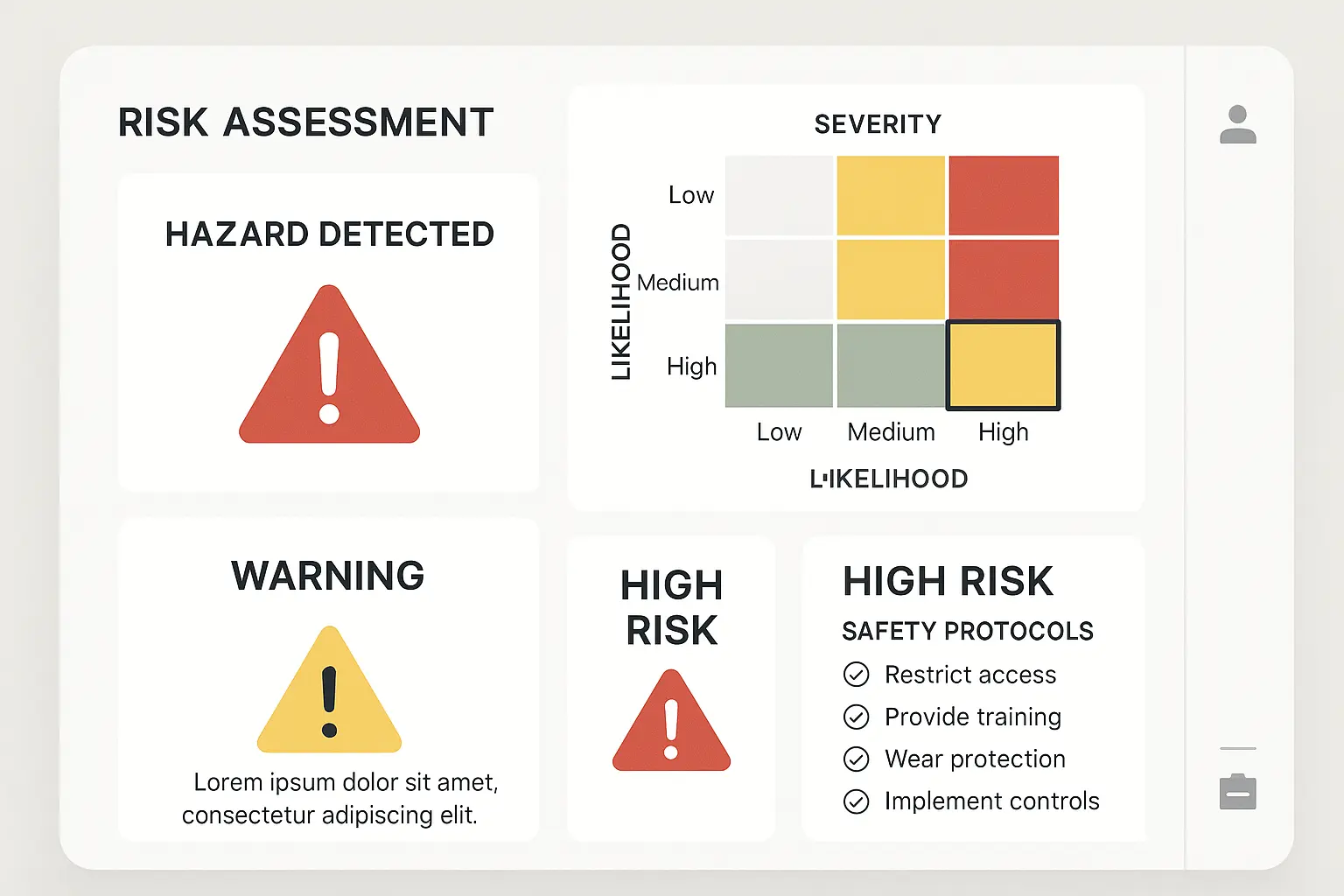

Risk Assessment: What Could Go Wrong

Look, I know what you’re thinking – what if it all goes wrong? Let me give you the straight talk on where these projects can crash and burn, because understanding the risks upfront can save you from expensive disasters.

High-Risk Territory

Complex AI systems represent the highest risk category. Technology immaturity and integration complexity can derail projects quickly. I’ve seen companies drop millions on AI platforms that never quite work as promised. The vendor demo looked amazing, but real life is messier.

Similar risk patterns emerge in enterprise implementations, as we’ve documented in our analysis of digital transformation challenges.

The key is phased rollouts, extensive testing periods, and strong vendor partnerships. Don’t bet the farm on unproven technology – start small and scale gradually. One client told me their biggest mistake was trying to automate everything at once.

Full facility automation projects carry massive business disruption risks. When Amazon redesigns a warehouse for Kiva robots, they’re essentially shutting down operations for months. High capital requirements compound the risk – you’re basically betting the company on getting it right.

The key is parallel operations during transition periods, comprehensive financial planning, and change management programs that prepare your team for the transformation.

|

Risk Level |

Automation Type |

Primary Risks |

Mitigation Strategies |

|---|---|---|---|

|

High |

AI Platforms, Full Robotic Systems |

Technology failure, Business disruption |

Phased rollouts, Parallel operations |

|

Medium |

AS/RS, Sortation, Collaborative Robots |

Integration complexity, Maintenance |

Vendor partnerships, Training programs |

|

Low |

Voice Technology, Wearables, Vision Systems |

User adoption, Learning curve |

Gradual implementation, Change management |

Medium-Risk Implementations

AS/RS and sortation systems present integration challenges and maintenance complexity. These are proven technologies, but they’re far from plug-and-play solutions. Vendor selection becomes critical – choose partners with track records in your industry.

Not every implementation goes smoothly. I’ve seen a $3M system sit unused for months because nobody planned for the learning curve. Maintenance contracts and comprehensive staff training programs help mitigate operational risks. Plan for the learning curve and budget accordingly.

Lower-Risk Options

Voice technology and collaborative robots offer the safest entry points into automation. The primary risks involve user adoption and temporary productivity disruption during training periods.

Comprehensive training programs and gradual implementation schedules address most concerns. These technologies typically enhance rather than replace existing processes, reducing change management challenges. The good news is, you don’t have to bet the farm on this stuff.

How The Marketing Agency Helps Automation Companies Scale

The warehouse automation industry presents unique marketing challenges that perfectly align with our expertise at The Marketing Agency. When you’re selling complex technical solutions with six-figure price tags and 18-month implementation timelines, generic marketing approaches fall flat on their face.

Market Analysis That Actually Works

Our scientific approach to market analysis helps automation vendors identify the most promising prospects. We analyze case study performance data to pinpoint which industries are ready for specific automation solutions. Instead of spray-and-pray marketing, we help you focus resources on decision-makers who are actually evaluating automation investments.

Competitive intelligence becomes crucial when buyers are comparing multiple vendors. We translate complex technical benefits into clear financial value propositions that resonate with CFOs and operations executives. What nobody talks about is how hard it is to communicate ROI for these complex systems.

Lead Generation for Complex B2B Sales

PPC campaigns ($750-$5,000/month) target decision-makers searching for specific automation solutions. We leverage case study data to create compelling ad copy highlighting proven ROI metrics. When someone searches “warehouse automation ROI,” they see your success stories, not generic product features.

Email marketing ($1,200-$10,000/month) develops sophisticated nurture campaigns that educate prospects about different automation categories. We use case study examples to demonstrate value at each stage of the buyer’s journey – from initial awareness through final vendor selection.

Inbound marketing strategies ($500-$3,000/month) create content strategies around case study insights, positioning you as the thought leader who understands real-world implementation challenges. When prospects research automation solutions, your expertise guides their decision-making process.

Data-Driven Optimization

The automation industry’s emphasis on measurable results mirrors our performance-focused approach. We monitor which case study content drives the most qualified leads, test different value propositions based on actual outcomes, and identify which marketing touchpoints most effectively move prospects through complex B2B sales cycles.

Attribution analysis becomes especially important when sales cycles stretch 12-18 months. We track every interaction from initial awareness through contract signing, helping you understand which marketing investments actually drive revenue.

Ready to transform your automation company’s marketing performance? We can discuss how our proven strategies help you reach more qualified prospects and accelerate your sales cycle.

Final Thoughts

Look, after diving deep into all these case studies, here’s my honest take: warehouse automation isn’t just coming – it’s already here. The companies crushing it right now aren’t necessarily the ones with the biggest budgets or fanciest tech. They’re the ones who picked the right solution for their specific mess and executed it well.

What strikes me most about these implementations is the diversity of approaches. Amazon’s massive robot armies work for their scale, but Walmart’s micro-fulfillment centers might be more practical for your operation. Voice technology offers quick wins, while AI platforms promise transformational change. The key is matching the solution to your specific challenges and constraints.

The financial reality is clear: automation requires significant upfront investment, but the returns justify the costs for companies that implement thoughtfully. ROI timelines range from 12 months for voice systems to 36+ months for complete facility overhauls, but every category shows positive returns when properly executed.

Your boss is probably going to ask about the risks, so let’s talk about that. Risk management becomes crucial as complexity increases. Start with lower-risk implementations to build internal expertise and confidence. Use these early wins to fund more ambitious projects like AS/RS systems or AI platforms.

The most successful implementations share common characteristics: thorough planning, realistic timelines, comprehensive training programs, and strong vendor partnerships. Companies that rush into automation without proper preparation often struggle with integration challenges and user adoption issues.

If I had to give you one piece of advice after seeing all this? Start small, learn fast, and don’t let perfect be the enemy of good. That voice picking system might not be as sexy as a robot army, but if it solves your problem and pays for itself in 18 months, that’s a win.

The automation train is leaving the station. The question isn’t whether to automate – it’s how quickly you can implement the right solutions for your operation. The question is whether you’re going to be on it or watching it disappear down the tracks.