Look, I’ll be straight with you – I’ve been obsessed with supply chains lately. Maybe it’s because I watched one too many news stories about empty store shelves, or maybe I’m just weird like that. But when I dug into the numbers, my jaw dropped. Companies doing this stuff right are cutting costs by 15% and filling orders 17% faster. Meanwhile, their competitors are still doing things the same way they did in 2005.

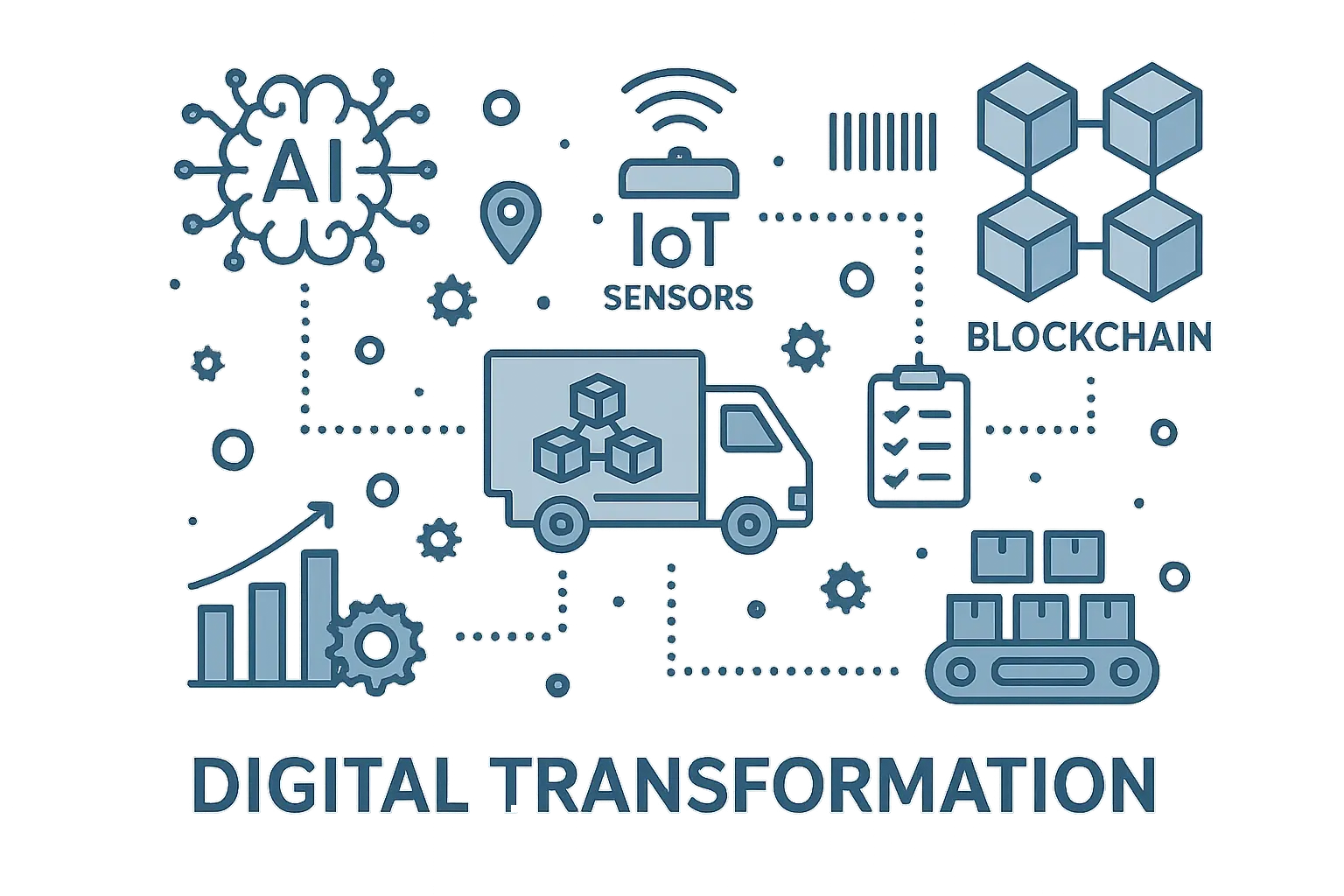

It really clicked when I realized how many businesses are still running on spreadsheets and prayer while their competitors are using AI, IoT, and blockchain to basically cheat at business (legally, of course). The supply chain world got turned upside down recently, and it exposed just how fragile most companies really are.

So I went down this rabbit hole and found 25 companies that didn’t just survive the chaos – they used it to build what can only be described as unfair advantages. Some of these stories will make you want to completely rethink how you do business. Others will make you realize you’re not as behind as you thought.

Table of Contents

-

Key Considerations for Evaluating Supply Chain Case Studies

-

Digital Transformation & Technology Integration Cases

-

Crisis Response & Supply Chain Resilience Examples

-

Sustainability & Circular Economy Innovations

-

E-commerce & Omnichannel Integration Strategies

-

Global Trade & Logistics Optimization Solutions

-

Manufacturing & Production Innovation Models

-

Detailed Analysis of Complex Implementations

-

Strategic Evaluation Framework

-

How The Marketing Agency Can Amplify Your Supply Chain Success

-

Final Thoughts

TL;DR

-

Don’t just copy what works for Amazon – figure out what actually fits your business first

-

AI and IoT aren’t magic bullets, but they’re becoming table stakes if you want to compete

-

Having a backup plan isn’t paranoid anymore – it’s survival 101

-

Going green actually saves money (who knew?)

-

Omnichannel isn’t just about having a website and a store – your whole supply chain needs a makeover

-

Early adopters of logistics AI are laughing all the way to the bank with 30-40% cost cuts

-

Smart factories work best when humans and machines team up, not when robots take over

-

Some of these solutions cost more than small countries – others you can start tomorrow with existing stuff

Key Considerations for Evaluating Supply Chain Case Studies

Here’s the thing – when I started digging into these success stories, I quickly realized that not all of them are created equal. You can’t just look at what Amazon does and think “great, I’ll do that too.” Trust me, companies have tried and failed spectacularly.

The first thing that matters is whether the case study actually solves problems like yours. A manufacturing company probably shouldn’t follow a retail giant’s playbook without some serious modifications. And honestly? ROI and actual performance improvements matter way more than having the coolest technology in the room.

Understanding competitive dynamics becomes crucial when evaluating supply chain transformations, particularly when examining how industry leaders have built competitive strategy frameworks that extend beyond operational efficiency to create market dominance.

|

What Actually Matters |

Pay Attention To This |

This Is Secondary |

This Is Just Hype |

|---|---|---|---|

|

Does It Fit Your Business? |

Real impact, measurable ROI |

Industry relevance, can it scale? |

Shiny new technology |

|

Can You Actually Do It? |

Resources you have, realistic timeline |

How complex it really is |

How much money it costs |

|

What If Things Go Wrong? |

Backup plans, crisis handling |

Multiple suppliers |

Insurance policies |

|

Environmental Stuff |

Cost savings, staying legal |

Brand image boost |

Marketing benefits |

|

Tech Integration |

Data setup, AI capabilities |

How automated it is |

Platform compatibility |

What tells the real story are the actual results. Last month, I talked to a logistics manager who spent $2M on fancy IoT sensors. Six months later? Their delivery times were exactly the same. Turns out they never actually looked at the data the sensors were collecting.

The best case studies show creative solutions to boring problems, not just expensive technology that looks impressive in PowerPoint presentations.

Risk management isn’t optional anymore – it’s survival 101. Recent global chaos taught us that having backup plans isn’t paranoid, it’s smart business. I focus on companies that proved they could adapt when everything went sideways – COVID, natural disasters, trade wars – because this stuff will happen again.

Here’s a reality check: imagine a mid-sized electronics company wanting to improve their supply chain. Instead of trying to copy Amazon’s AI-powered crystal ball (which needs massive data infrastructure they don’t have), they might start with something like DHL’s warehouse sensors – way more doable, still delivers real improvements, and builds the foundation for fancier stuff later.

Sustainability isn’t just feel-good marketing anymore. The smartest companies figured out that going green often means saving green. Plus, customers actually care about this stuff now, and regulations are getting stricter.

Implementation feasibility might be the most ignored factor. Some solutions require resources that only Fortune 500 companies have, while others can work for smaller companies if you get creative.

Digital Transformation & Technology Integration Cases

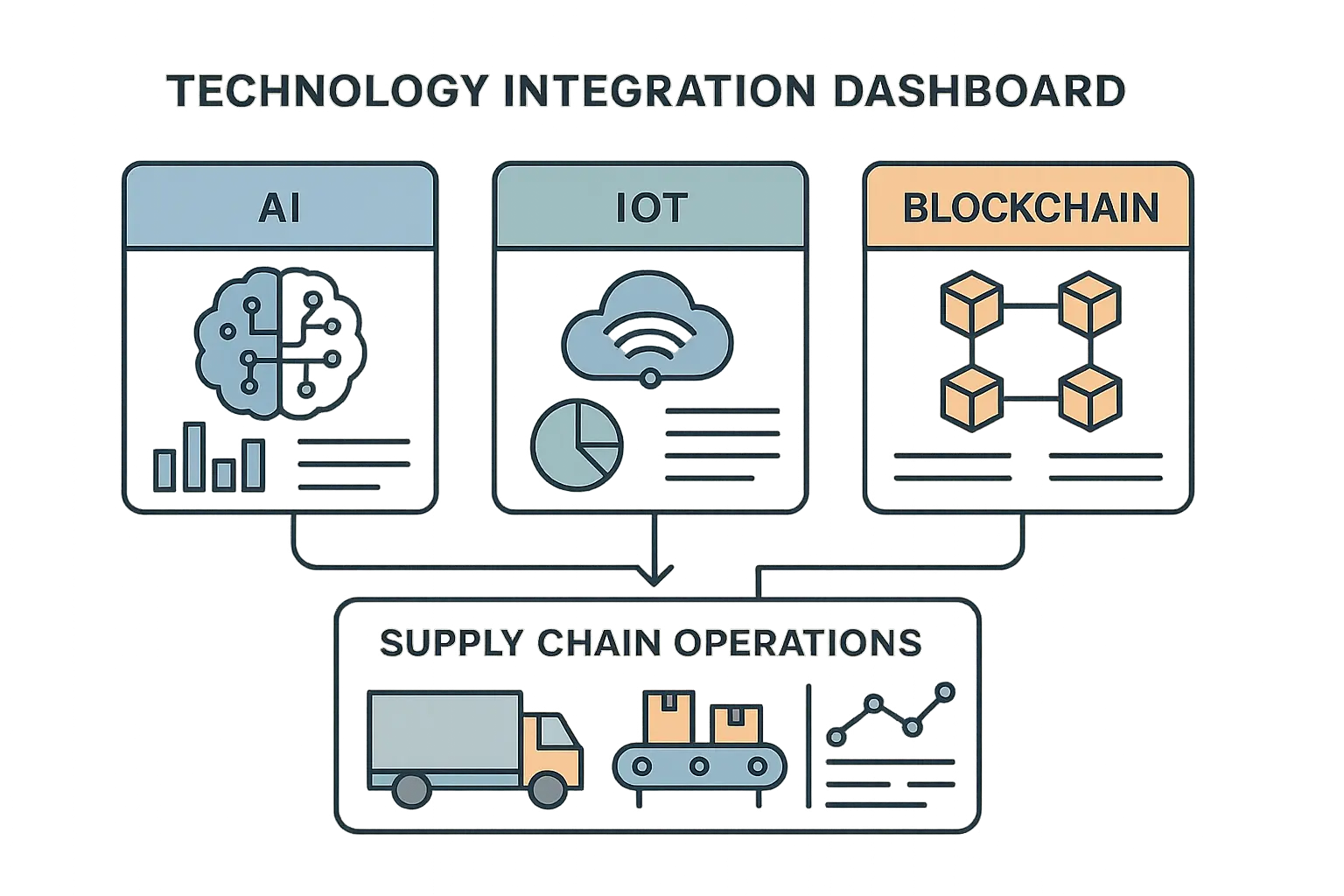

Digital transformation in supply chains is basically about three things: AI that can predict the future (sort of), IoT sensors that turn everything smart, and blockchain that makes everything transparent. The companies doing this right are seeing 40-50% improvements in pretty much everything – forecasting, efficiency, customer happiness. But here’s the catch: success requires a solid data foundation, not just random tech gadgets.

1. Amazon’s AI-Powered Predictive Analytics Revolution

Amazon’s machine learning setup across their global warehouse network is basically the gold standard for computer fortune-telling in supply chains. They’ve cut forecasting errors in half using deep learning models that simultaneously process customer behavior, weather patterns, economic indicators, and seasonal trends.

The success of Amazon’s AI implementation demonstrates how creating continuously learning systems can transform traditional supply chain operations into adaptive, self-optimizing networks that improve performance over time.

But the real magic isn’t just the technology – it’s how everything works together. Amazon’s system makes real-time inventory adjustments across 175+ fulfillment centers while maintaining 99.7% order accuracy through automated quality control. This level of coordination would be impossible without their massive data infrastructure.

What blew my mind is how they’ve automated decisions that used to need humans. Their algorithms automatically adjust inventory levels, pricing, and purchasing based on predictive models that crunch through 500+ million data points daily. That’s like processing every tweet sent in a day, but for inventory decisions.

2. DHL’s IoT-Enabled Smart Warehousing Initiative

DHL stuck 15,000+ IoT sensors across their warehouse network – basically putting a smart sensor on everything that moves (and some things that don’t). The results speak for themselves: 30% less energy use and 40% less equipment breaking down.

Their predictive maintenance catches problems before they happen, while real-time tracking sped up order processing by 25%. The smart climate control alone saves serious money while keeping sensitive products at the right temperature.

What I liked about their approach was the gradual rollout instead of trying to transform everything overnight. Made it way easier for their workers to adapt instead of freaking out about all the new tech.

3. Maersk’s Digital Twin Container Shipping Platform

Maersk basically said “screw it, we’re going full sci-fi” and built digital twins of their entire operation – 700+ ships and 50+ ports. Think of it as having a video game version of your entire business that you can test stuff on before doing it for real.

Their digital twin platform combines real-time weather data with route optimization algorithms, cutting fuel use by 12% while getting ships to their destinations on time more often. The predictive maintenance part prevents 85% of potential equipment failures by analyzing sensor data from across their fleet.

Customer satisfaction scores jumped 35% because they could actually tell people what was happening with their cargo and offer alternatives when things went wrong. This isn’t just about technology – it’s about reimagining how global shipping can work when you have all the data.

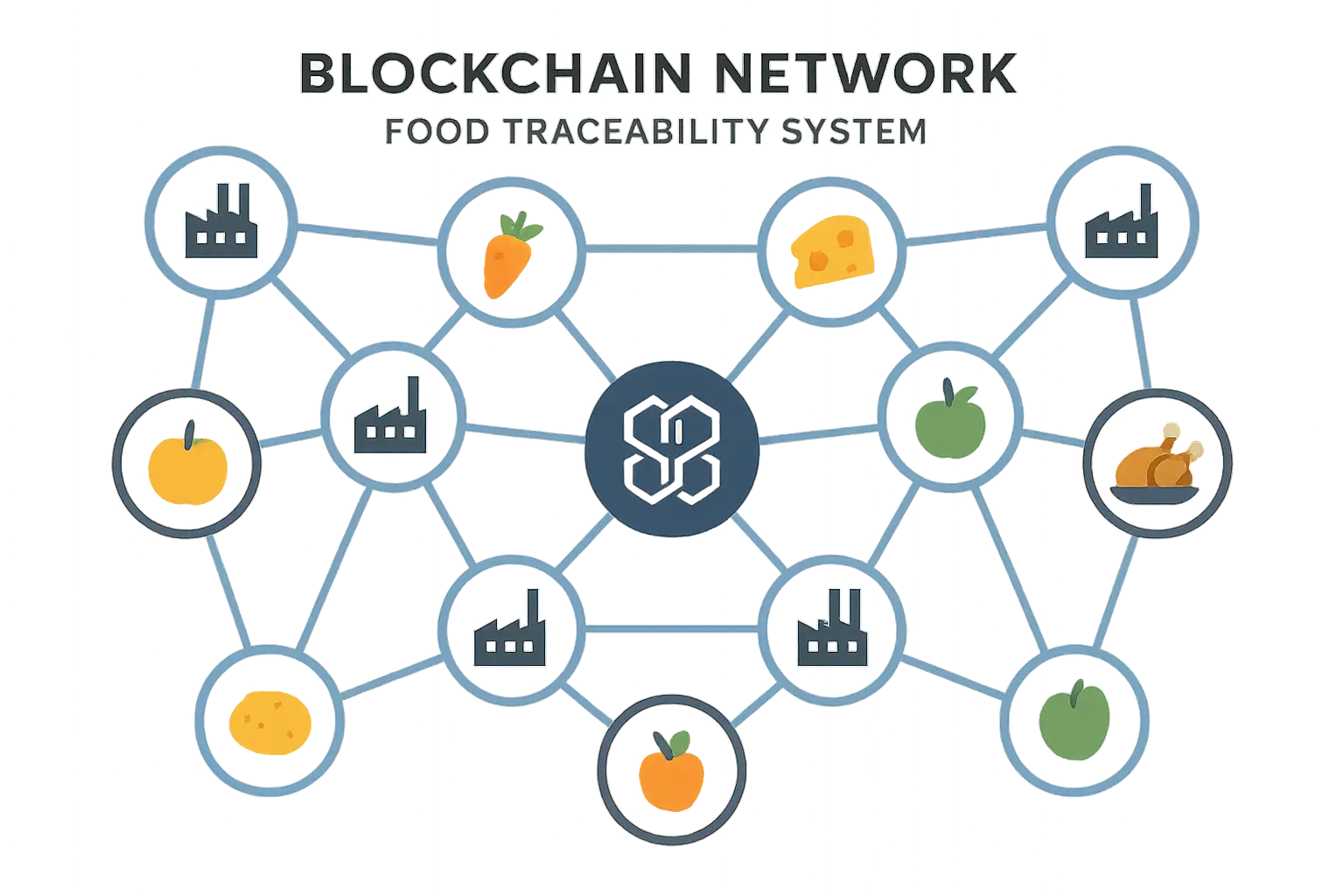

4. Walmart’s Blockchain Food Traceability System

Walmart got tired of playing detective every time someone got food poisoning. Their blockchain implementation transformed food safety incident response from weeks of investigation to seconds of knowing exactly what happened.

They’ve got 100+ suppliers on their blockchain network, creating complete transparency for leafy greens, pork, and other risky products. Think of it as a permanent receipt that nobody can fake or lose.

The system cut food waste by 20% through better expiration date management while giving customers unprecedented visibility into where their food actually comes from.

The regulatory compliance benefits are huge, but the customer trust factor might be even more valuable in today’s “I want to know everything about what I’m buying” market.

5. FedEx’s Autonomous Last-Mile Delivery Robots

FedEx’s robot delivery pilot program pulled off 500+ successful deliveries in Memphis and other test cities, cutting last-mile delivery costs by 60% for small packages. The cool part is how they integrated with existing systems and customer notifications – it enhances what they already do instead of replacing everything.

They’ve got regulatory approval in 5 states, proving that robot deliveries are moving from sci-fi to reality. The cost savings for urban deliveries could be massive, especially as paying humans to drive around gets more expensive.

6. Tesla’s Vertical Integration Manufacturing Model

Tesla’s approach to controlling their entire supply chain from raw materials to finished cars has cut battery production costs by 40% while letting them iterate products super fast through software-defined manufacturing.

Their direct relationships with lithium and cobalt suppliers eliminate middleman markups while ensuring they won’t run out of materials. The Gigafactory model enables rapid scaling and cost reduction through economies of scale that traditional car companies struggle to match.

Fair warning: the vertical integration strategy requires massive capital investment, but it gives unprecedented control over quality, costs, and how fast you can innovate.

Crisis Response & Supply Chain Resilience Examples

Crisis response capabilities went from “nice to have” to “absolutely essential for survival” pretty quickly. The companies that thrived during global chaos combined supplier diversification, flexible manufacturing, and real-time visibility systems. These cases show that resilient supply chains need proactive planning, not just scrambling when things go wrong.

7. Toyota’s COVID-19 Supply Chain Adaptation

Toyota did what Toyota does – they made handling a global pandemic look easy while everyone else panicked. They activated 200+ backup suppliers within 30 days while implementing health protocols that kept 95% of production running throughout the crisis.

Their ability to shift production lines to make ventilators and medical equipment showed manufacturing flexibility that most companies can only dream of. Balancing their famous just-in-time approach with building strategic inventory buffers required some seriously sophisticated planning.

What impressed me most was how they handled supplier relationships during the crisis – instead of just demanding performance, they actually strengthened partnerships by sharing resources and expertise.

During those crazy early COVID months, Toyota’s supplier team did weekly check-ins with their top 500 suppliers, offering financial support and technical help to keep operations running. This approach resulted in 95% supplier retention compared to industry averages of 70-80%, proving that crisis response can actually strengthen relationships instead of destroying them.

8. Unilever’s Multi-Sourcing Risk Mitigation Strategy

Unilever mapped 70,000+ suppliers across 5 levels of their supply chain, implementing dual-sourcing for 90% of critical materials. Their regional supply hub strategy reduces transportation risks while their supplier financial health monitoring system provides early warning of potential disruptions.

The systematic approach to identifying and mitigating risks creates redundancy without going crazy on costs. Their supplier diversification strategy proved invaluable during recent global chaos.

9. Apple’s Supply Chain Diversification from China

Apple’s strategic shift moved 20% of iPhone production to India and Vietnam while investing $1B+ in supplier facilities outside China. They maintained their legendary quality standards while reducing geopolitical risk through geographic diversification.

Creating backup supply chains for critical components ensures production continues regardless of regional disruptions. This proactive approach to geopolitical risk management sets the standard for global tech companies.

10. Pfizer’s Vaccine Distribution Cold Chain Management

Pfizer created an ultra-cold supply chain network that keeps vaccines at -70°C throughout global distribution. Their GPS-tracked thermal shippers with 10-day cold life enabled delivery of 3+ billion vaccine doses while maintaining effectiveness.

Coordinating with 100+ countries for regulatory and logistics compliance during a global emergency showed supply chain agility at unprecedented scale. The cold chain infrastructure they built continues to benefit other pharmaceutical products.

11. General Motors’ Semiconductor Shortage Response

GM’s response to the global chip shortage included prioritizing high-margin vehicle production while redesigning vehicles to use fewer or different chips. They invested in direct supplier relationships, bypassing traditional structures to gain better visibility and control.

GM’s adaptive crisis management approach mirrors successful competitive response strategies that companies use to maintain market position during industry disruptions and supply constraints.

Real-time visibility into semiconductor supply chains helped them make smart production decisions during the shortage. Their adaptive strategies maintained profitability despite significant supply constraints.

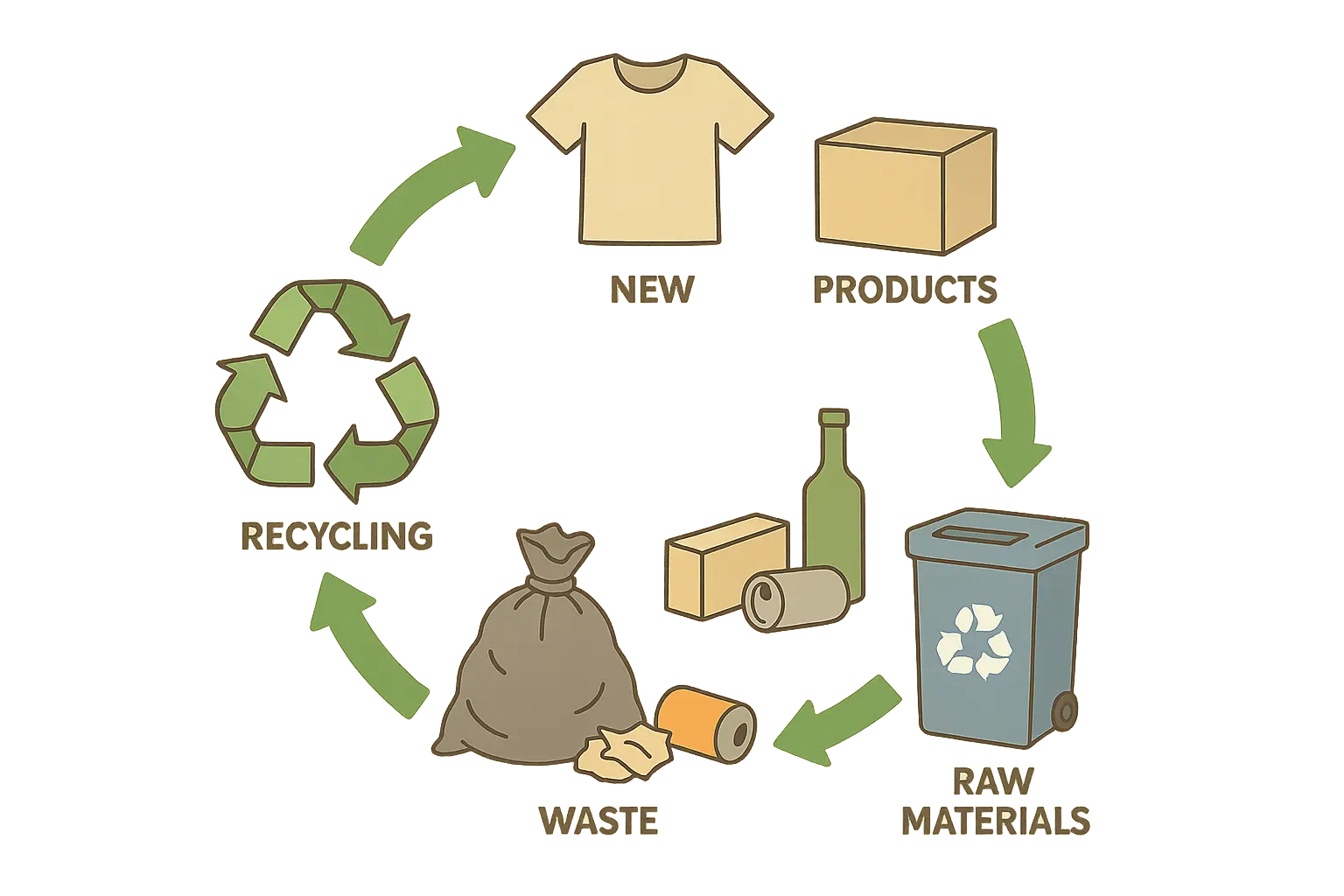

Sustainability & Circular Economy Innovations

Sustainability initiatives in supply chain management are generating real business value through cost reduction, premium pricing, and staying ahead of regulations. Leading companies are implementing circular economy principles that extend product lifecycles, reduce waste, and create new revenue streams. These cases prove that being environmentally responsible and making money aren’t mutually exclusive – they actually reinforce each other.

12. Patagonia’s Circular Supply Chain Initiative

Patagonia’s Worn Wear program extends product life by 75% while their take-back program processes 100, 000+ garments annually. Recycled materials now make up 70% of their product line, proving that circular economy principles can actually scale in manufacturing.

Their supplier partnerships focus on regenerative agriculture, creating positive environmental impact throughout their supply chain. The circular model generates serious customer loyalty while reducing raw material costs.

13. IKEA’s Renewable Materials Transformation

IKEA’s commitment to using only renewable and recycled materials by 2030 has already hit 60% renewable material usage across their product line. They’ve invested €2B in renewable energy and materials innovation while ditching single-use plastics in their restaurants.

Their furniture buyback programs create circular business models that generate additional revenue while reducing waste. The scale of their transformation proves that sustainability initiatives can work for mass-market retailers.

|

Sustainability Move |

Environmental Impact |

Business Value |

How Long It Takes |

|---|---|---|---|

|

Circular Economy Programs |

40-60% waste reduction |

15-25% cost savings |

2-3 years |

|

Renewable Materials |

50-80% carbon footprint reduction |

10-20% premium pricing |

3-5 years |

|

Energy Efficiency |

20-40% energy consumption reduction |

5-15% operational savings |

1-2 years |

|

Sustainable Packaging |

30-70% packaging waste reduction |

8-18% material cost savings |

1-3 years |

|

Carbon Neutral Operations |

Net-zero emissions |

Brand differentiation |

5-10 years |

14. Interface Inc.’s Carbon Negative Supply Chain

Interface’s Mission Zero initiative reduced carbon intensity by 96 % since 1996 while achieving carbon neutral manufacturing in 2020. Their bio-based carpet materials from agricultural waste create regenerative supply chains that actually sequester more carbon than they emit.

The environmental achievements generate cost savings through energy efficiency while creating premium positioning in commercial markets. Their carbon negative goal represents the next evolution in sustainable manufacturing.

15. Adidas’ Ocean Plastic Product Line

Adidas produced 30+ million pairs of shoes from ocean plastic through their partnership with Parley for the Oceans. They’ve diverted 2,810 tons of plastic waste from oceans while creating a scalable model for turning trash into treasure.

The premium pricing for sustainable products proves that environmental initiatives can actually boost profitability instead of hurting it. Their innovation in waste-to-product manufacturing opens new possibilities for circular economy business models.

16. Unilever’s Sustainable Living Brands Initiative

Unilever’s 28 Sustainable Living Brands generate 75% of company growth while reducing environmental footprint. They achieved zero waste to landfill across all factories while sourcing 62% of agricultural raw materials sustainably.

The brand transformation proves that sustainability can drive business growth rather than limit it. Their approach shows how environmental initiatives can become competitive advantages in consumer markets.

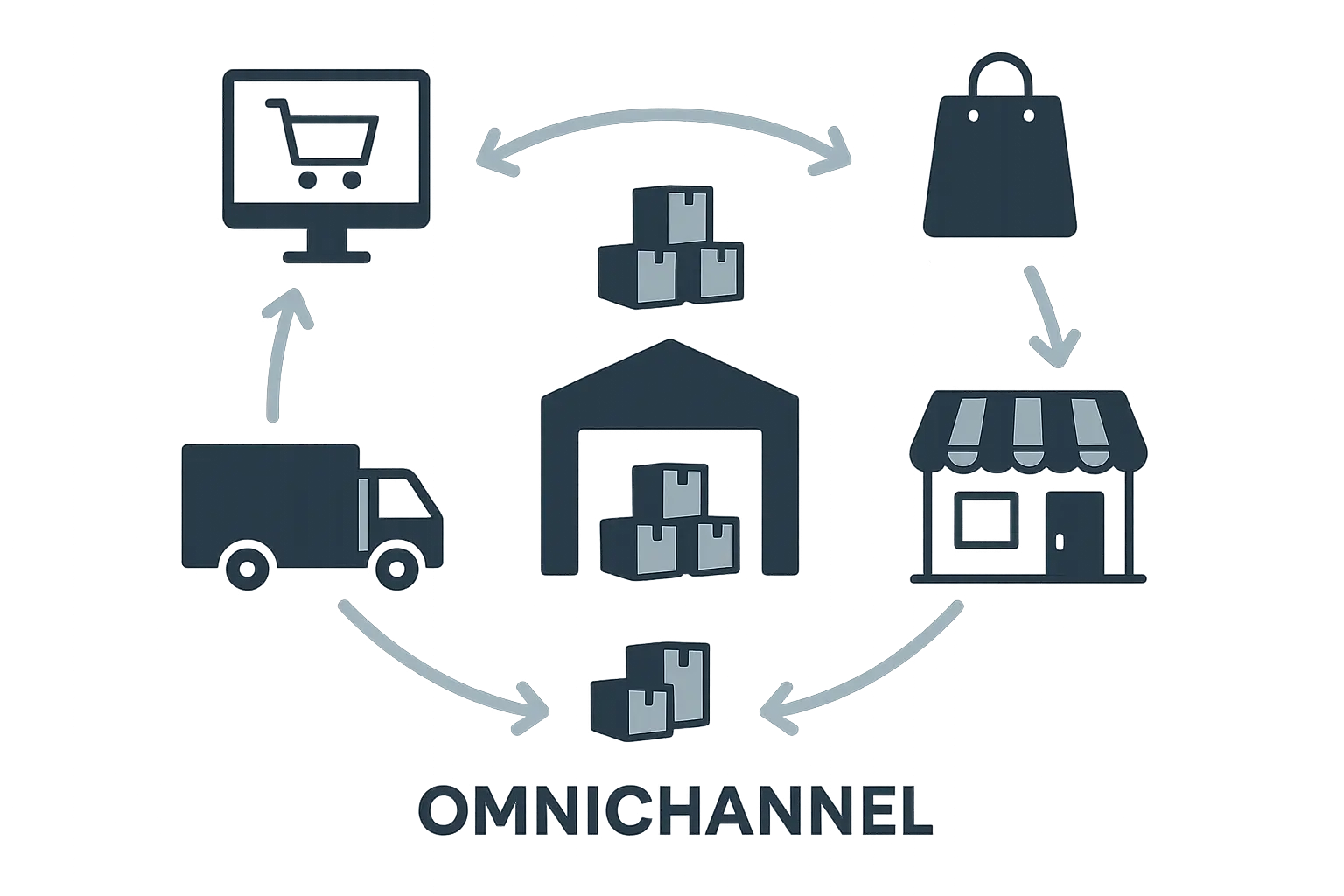

E-commerce & Omnichannel Integration Strategies

E-commerce and omnichannel integration require completely rethinking your supply chain to support multiple fulfillment channels at once. Successful implementations combine inventory visibility, flexible fulfillment networks, and customer experience optimization. These cases show that omnichannel success depends on supply chain capabilities, not just having a fancy website.

17. Zara’s Fast Fashion Supply Chain Revolution

Zara’s vertically integrated supply chain enables 2-week design-to-shelf cycles through proximity manufacturing with 50% of production within 1,000 km of headquarters. Their vertical integration controls 60% of production while real-time sales data drives production decisions.

Limited production runs create scarcity while reducing waste, showing how supply chain strategy can actually enhance brand positioning. Their speed-to-market capabilities create competitive advantages that are incredibly difficult to copy.

18. Best Buy’s Omnichannel Fulfillment Network

Best Buy transformed 1,000+ stores into mini-distribution centers, enabling same-day delivery to 60% of the US population. Real-time inventory visibility across all channels supports seamless customer experiences while curbside pickup hit 40% of online orders.

Their omnichannel integration leverages existing store infrastructure instead of requiring massive new investments. The transformation shows how traditional retailers can actually compete with pure-play e-commerce companies.

Best Buy’s “ship from store” capability lets them fulfill 35% of online orders directly from retail locations. When someone orders online, their system automatically finds the nearest store with inventory, cutting shipping time from 3-5 days to next-day delivery while optimizing inventory turnover.

19. Nike’s Direct-to-Consumer Supply Chain Pivot

Nike increased direct sales from 30% to 40% of total revenue while cutting wholesale partnerships by 50%. They invested $1B+ in digital infrastructure and fulfillment capabilities, achieving 25% higher margins through direct sales.

The supply chain reconfiguration supports premium customer experiences while boosting profitability. Their DTC transformation shows how established brands can reduce dependence on traditional retail channels.

20. Shopify’s Fulfillment Network for SME Merchants

Shopify’s fulfillment network enables small merchants to compete with retail giants through strategically located fulfillment centers and integration with 100+ shipping carriers. Their inventory management tools provide demand forecasting capabilities while cutting shipping costs by 30%.

The platform democratizes advanced supply chain capabilities for smaller businesses that couldn’t afford to build these systems independently. Their SME focus creates a completely different competitive dynamic than Amazon’s approach.

21. Alibaba’s New Retail Integration Model

Alibaba’s integration of online and offline retail includes real-time inventory synchronization across channels and 30-minute delivery in major Chinese cities. AI-powered demand prediction at store level enables seamless customer experiences across all touchpoints.

Their New Retail model shows how digital and physical retail can be truly integrated instead of just connected. The scale of their implementation in China provides insights for global retail transformation.

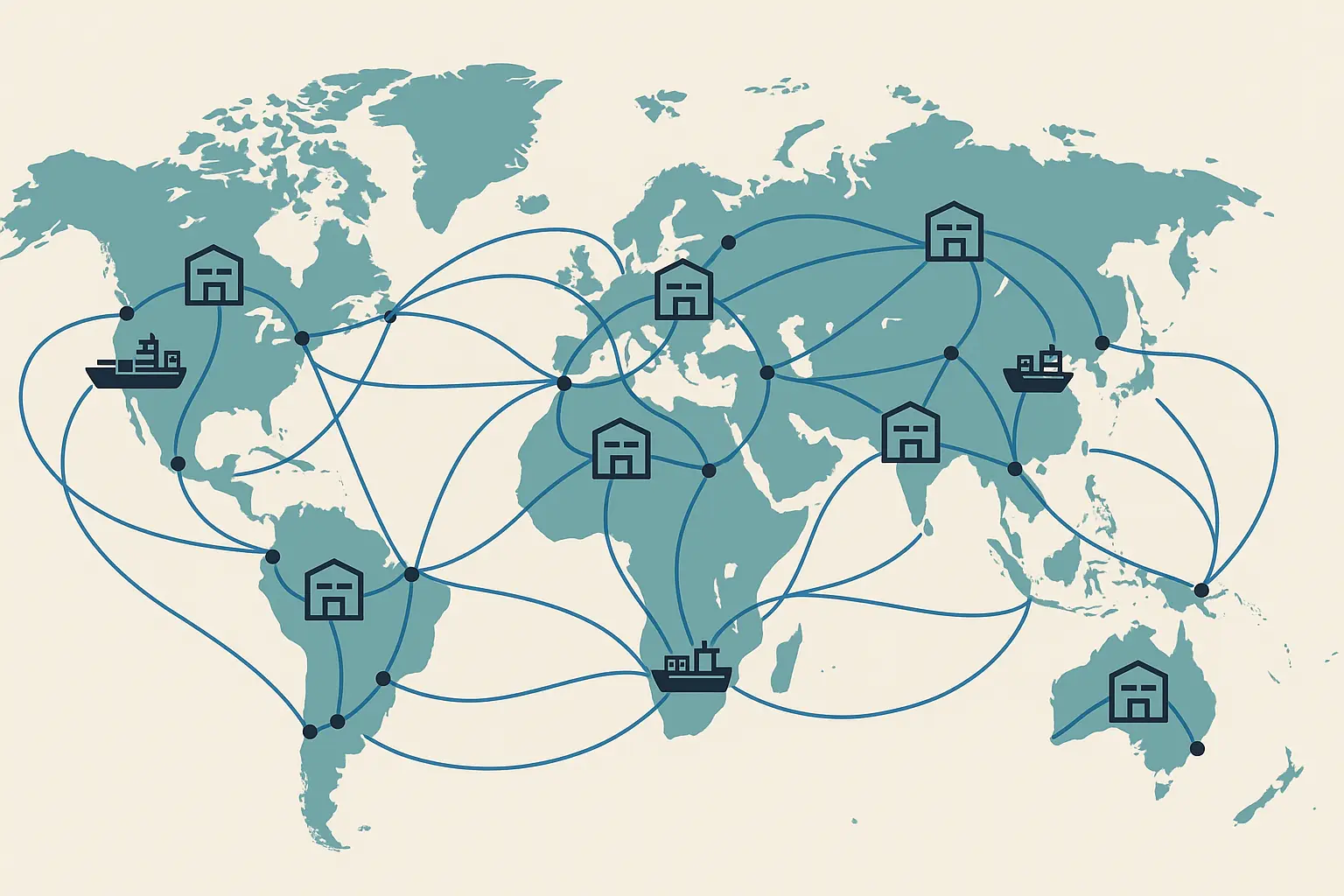

Global Trade & Logistics Optimization Solutions

Global trade and logistics optimization through AI and automation is generating 30-40% cost reductions for early adopters. Advanced algorithms for route optimization, freight matching, and capacity planning are transforming traditional logistics operations. These cases show that digital transformation in logistics requires comprehensive platform approaches rather than random tech solutions.

22. C.H. Robinson’s AI-Powered Freight Optimization

C.H. Robinson’s Navisphere platform processes 17 million shipments annually using machine learning algorithms that cut empty miles by 35%. Predictive analytics for capacity planning and pricing provide real-time visibility for 125,000+ customers.

Their AI implementation shows how traditional logistics companies can transform through technology while keeping their core service relationships. The scale of their platform creates network effects that benefit everyone using it.

23. UPS’s ORION Route Optimization System

UPS’s advanced algorithms optimize delivery routes for 55,000+ drivers, reducing daily miles driven by 100+ million miles annually while saving 10+ million gallons of fuel per year. Delivery efficiency improved by 10-15% while customer service got better through more accurate delivery windows.

The ORION system shows how mathematical optimization can generate massive operational improvements at scale. Their route optimization principles work for pretty much any delivery operation.

24. Flexport’s Digital Freight Forwarding Platform

Flexport’s digitization of traditional freight forwarding provides real-time shipment tracking for ocean, air, and ground freight while automating customs clearance to cut delays by 40%. Their integrated platform connects 10,000+ suppliers and buyers with transparent pricing that eliminates hidden fees.

The digital transformation of freight forwarding shows how technology can modernize old-school industries. Their user-friendly approach reduces complexity for companies without extensive logistics expertise.

Manufacturing & Production Innovation Models

Manufacturing innovation focuses on human-machine collaboration through Industry 4.0 implementations that combine AI, robotics, and predictive analytics. Smart factory transformations achieve quality improvements and cost reductions while enabling mass customization capabilities. These cases show that successful manufacturing innovation enhances rather than replaces human capabilities.

25. BMW’s Smart Factory Industry 4.0 Implementation

BMW’s smart factory transformation includes 3,000+ robots working alongside humans in collaborative environments with AI-powered quality control achieving 99.9% defect detection. Predictive maintenance cut unplanned downtime by 70% while enabling mass customization for 1 million+ vehicle configurations.

The human-machine collaboration model proves that automation enhances rather than replaces skilled workers. Their Industry 4.0 implementation creates competitive advantages through quality, efficiency, and customization capabilities that traditional manufacturing approaches simply can’t match.

Detailed Analysis of Complex Implementations

Complex supply chain transformations require systematic implementation approaches that combine technology infrastructure, organizational change management, and performance measurement systems. The most successful implementations follow phased rollout strategies with continuous monitoring and optimization. These detailed analyses reveal the critical success factors that separate transformational initiatives from expensive technology failures.

Amazon’s AI-Powered Predictive Analytics Revolution (Deep Dive)

Amazon’s challenge involved managing inventory across a rapidly expanding global network while keeping customers happy through fast delivery and product availability. Their solution architecture deployed ensemble methods combining neural networks, gradient boosting, and time series analysis.

The data integration connected customer behavior, competitor pricing, weather data, economic indicators, and social media sentiment into one unified platform. Real-time processing handles 500+ million data points daily while automated decision-making systems adjust inventory levels, pricing, and procurement without human intervention.

Their implementation started with building data lakes storing petabytes of historical and real-time data. Model development created specialized algorithms for different product categories and geographic regions. A/B testing continuously validated model performance against traditional forecasting methods during phased rollout across fulfillment centers.

The results transformed their business: forecasting accuracy improved from 75% to 88% across product categories while inventory holding costs dropped by $1.2B annually. Customer satisfaction scores increased by 15% due to better product availability, and supplier relationships strengthened through more accurate demand signals.

Maersk’s Digital Twin Container Shipping Platform (Deep Dive)

Maersk needed to optimize operations across a complex global shipping network while reducing environmental impact and improving customer service. Their digital twin architecture created replicas of vessels, containers, ports, and cargo while incorporating real-time weather, ocean conditions, and port congestion data.

The technical implementation deployed 100,000+ IoT sensors across their fleet monitoring location, condition, and performance. Satellite connectivity ensured continuous data transmission from vessels at sea while cloud computing utilized edge processing for real-time analysis and cloud storage for historical data.

Operational transformation included dynamic routing based on weather, fuel prices, and port availability. Predictive maintenance scheduled during optimal windows reduced vessel downtime while capacity management optimized container loading and vessel utilization in real-time.

Results included 12% fuel consumption reduction through optimized routing and on-time performance improvement from 70% to 85%. Maintenance costs decreased by 20% through predictive scheduling while customer satisfaction scores increased by 35%. The platform reduced carbon emissions by 1.5 million tons annually.

Strategic Evaluation Framework

Evaluating supply chain case studies requires systematic assessment across strategic alignment, technology integration, risk management, sustainability impact, and implementation feasibility. High-impact cases show exceptional ROI with scalable solutions, while moderate impact cases provide solid operational improvements. The evaluation framework helps identify which innovations can be adapted to different organizational contexts and resource constraints.

Strategic Alignment & Business Impact Assessment

High-impact cases show exceptional ROI with $1.2B annual savings and scalability across industries. Tesla’s vertical integration creates strategic differentiation enabling cost leadership and innovation control. Walmart’s blockchain provides immediate food safety benefits while building customer trust.

Moderate impact cases like DHL’s IoT warehousing generate good operational improvements but limited strategic differentiation. Best Buy’s omnichannel approach enhances customer experience but represents industry-standard practices rather than breakthrough innovation.

Technology Integration Excellence

Innovation leaders create cutting-edge competitive advantages through advanced technology implementation. C.H. Robinson’s AI optimization generates measurable efficiency gains through sophisticated algorithms. BMW’s smart factory demonstrates Industry 4.0 leadership with successful human-machine collaboration.

Emerging technology adopters including FedEx’s autonomous delivery show early-stage innovation with high future potential. Flexport’s digital platform modernizes traditional freight forwarding through comprehensive technology integration.

Risk Management & Resilience Evaluation

Crisis response champions demonstrated exceptional agility during global disruptions. Toyota’s COVID adaptation maintained operational excellence while showing remarkable flexibility. Pfizer’s vaccine distribution successfully managed unprecedented logistics challenges at global scale.

Apple’s supply diversification shows proactive risk mitigation reducing geopolitical exposure. Unilever’s multi-sourcing provides systematic risk identification and mitigation strategies.

|

Case Study Category |

How Complex Is It? |

When You’ll See ROI |

How Well It Scales |

|---|---|---|---|

|

AI/Predictive Analytics |

Pretty Complex |

12-18 months |

Scales Really Well |

|

IoT/Smart Operations |

Medium Complexity |

6-12 months |

Scales Okay |

|

Blockchain Transparency |

Medium Complexity |

9-15 months |

Scales Okay |

|

Crisis Response Systems |

Not Too Complex |

3-6 months |

Scales Really Well |

|

Sustainability Programs |

Medium-High Complexity |

18-36 months |

Scales Really Well |

|

Omnichannel Integration |

Pretty Complex |

12-24 months |

Scales Okay |

|

Manufacturing Innovation |

Pretty Complex |

18-30 months |

Doesn’t Scale Great |

Sustainability Leadership

Environmental pioneers show industry-leading environmental impact with measurable carbon sequestration. Patagonia’s circular model implements comprehensive circular economy principles with strong customer engagement.

IKEA’s renewable materials initiative demonstrates ambitious 2030 targets with clear progress milestones and substantial investment commitments.

Implementation Feasibility Analysis

High feasibility solutions for most organizations include Best Buy’s omnichannel approach leveraging existing store infrastructure with moderate technology investment. Zara’s fast fashion principles apply across industries requiring speed-to-market capabilities.

Moderate feasibility options requiring significant investment include Walmart’s blockchain with clear ROI pathways and Nike’s DTC pivot demanding substantial digital capabilities.

Low feasibility solutions limited to industry leaders include Tesla’s vertical integration requiring massive capital investment and Amazon’s AI platform needing extensive data infrastructure and machine learning capabilities.

How The Marketing Agency Can Amplify Your Supply Chain Success

Your supply chain transformation deserves marketing strategies that match their sophistication. The same data-driven principles driving supply chain optimization – predictive analytics, real-time adjustment, and measurable outcomes – power our approach to digital marketing.

We’ve seen companies invest millions in supply chain improvements only to struggle with communicating these advantages to customers. Whether you’re implementing sustainable practices, adopting AI optimization, or creating omnichannel experiences, we help identify the gaps most agencies miss in translating operational excellence into market visibility.

Our comprehensive approach to market analysis combines traditional competitive intelligence with advanced analytics for strategic growth, ensuring your supply chain innovations translate into measurable market advantages and customer acquisition.

The transparency and performance measurement emphasized throughout these case studies reflects our commitment to sharing real insights rather than vanity metrics, much like how we approach answer engine optimization to ensure your content reaches customers through next-generation search technologies.

Ready to ensure your supply chain innovations reach their full market potential? We can discuss how our scientific approach to market analysis can amplify your operational advantages.

Final Thoughts

These 25 supply chain case studies reveal that transformation success depends more on strategic thinking and systematic implementation than on technology alone. The companies that achieved breakthrough results combined advanced technology with organizational agility, risk management, and customer focus.

The most striking pattern across all successful cases is their commitment to measurable outcomes and continuous optimization. Whether reducing costs by billions, improving efficiency by double digits, or creating entirely new business models, these leaders prove that supply chain excellence drives competitive advantage in ways that are difficult for competitors to replicate.

Here’s the real talk: implementation feasibility varies dramatically, but the principles underlying these successes – data-driven decision making, customer-focused design, and systematic risk management – apply regardless of your company size or industry. The key is picking the right combination of strategies that align with your specific challenges and capabilities.

Supply chain transformation isn’t just about operational efficiency anymore. It’s about creating sustainable competitive advantages that drive growth, enhance customer relationships, and build resilience for future disruptions. The companies featured in these case studies didn’t just optimize their operations – they reimagined what’s possible in their industries.

Your move: Pick one thing from this list and actually try it. Your future self will thank you.