Table of Contents

-

Understanding Volume Calculator Fundamentals

-

Basic Geometric Shape Calculators

-

Advanced Container Volume Solutions

-

Industry-Specific Volume Applications

-

Digital Integration and Automation Features

-

Best Practices for Accurate Measurements

-

Choosing the Right Calculator Platform

-

Final Thoughts

TL;DR

-

Volume calculators range from simple geometric tools to complex industrial systems that integrate with business software

-

Cube calculators need just one measurement, while cones require radius and height for accurate results

-

Tank and tube calculators handle specialized applications with features for partial fills and wall thickness considerations

-

Modern platforms offer API integration, real-time calculations, and mobile-responsive designs for field use

-

Construction, manufacturing, and chemical industries each require specific calculator features and compliance standards

-

Measurement accuracy directly impacts calculation quality – choose appropriate tools for your precision requirements

-

Online platforms provide advanced features like calculation history, batch processing, and team collaboration capabilities

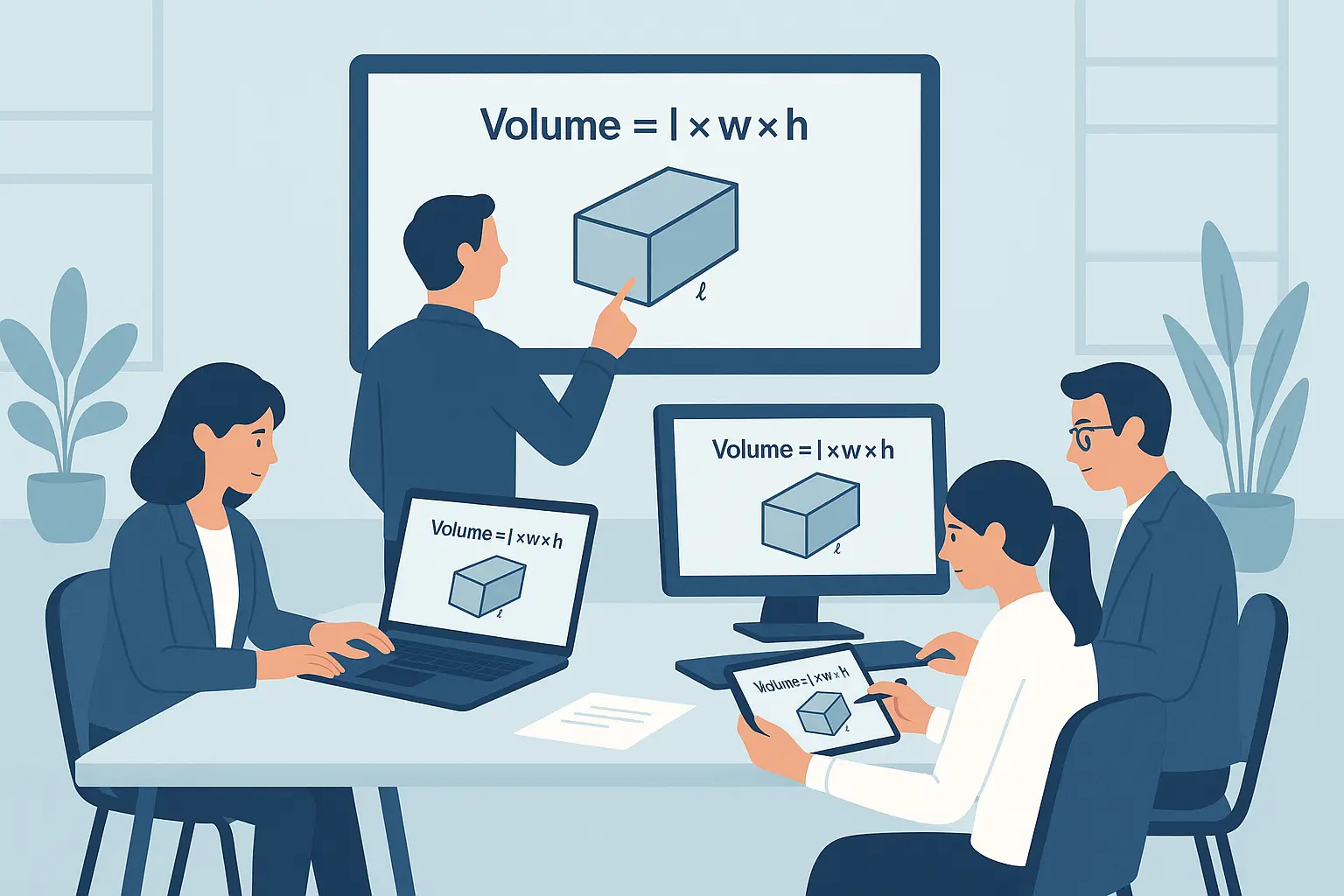

Understanding Volume Calculator Fundamentals

Why Volume Calculations Matter More Than You Think

Last month, I watched a construction crew order $3,000 worth of extra concrete because their volume calculations were off by just 15%. It got me thinking about how these “simple” calculations can make or break a project.

Look, I’ve been working with volume calculator applications across different industries for years, and let me tell you – getting these measurements wrong will absolutely wreck your project. Whether you’re figuring out how much concrete to order, sizing up storage tanks, or calculating material costs, one bad measurement can blow your budget.

Here’s the thing about volume – it’s just measuring how much space something takes up. We use cubic meters as the standard unit that engineers use worldwide, but honestly, most of us are just trying to make sure we order enough materials without going overboard. Modern businesses run on data these days, and volume calculations? They’re absolutely crucial for managing inventory and keeping costs under control. Miss your measurements, and you’re either scrambling for more materials or stuck with expensive overstock.

Volume calculator tools have come a long way from the days when you had to bust out formulas and do conversions by hand. Now? You’re making smart business decisions based on solid data instead of educated guesses. And trust me, your wallet will thank you for the precision.

The Evolution of Digital Volume Tools

Remember when you had to apply formulas manually and convert units separately? What a pain. Modern volume calculator systems handle all that grunt work automatically, plus they play nice with your existing software.

What gets me excited about today’s volume calculator tech is how it cuts down on human error while speeding everything up. You can crunch hundreds of calculations in the time it used to take for maybe a dozen manual ones. That’s a game-changer when you’re under deadline pressure.

Basic Geometric Shape Calculators

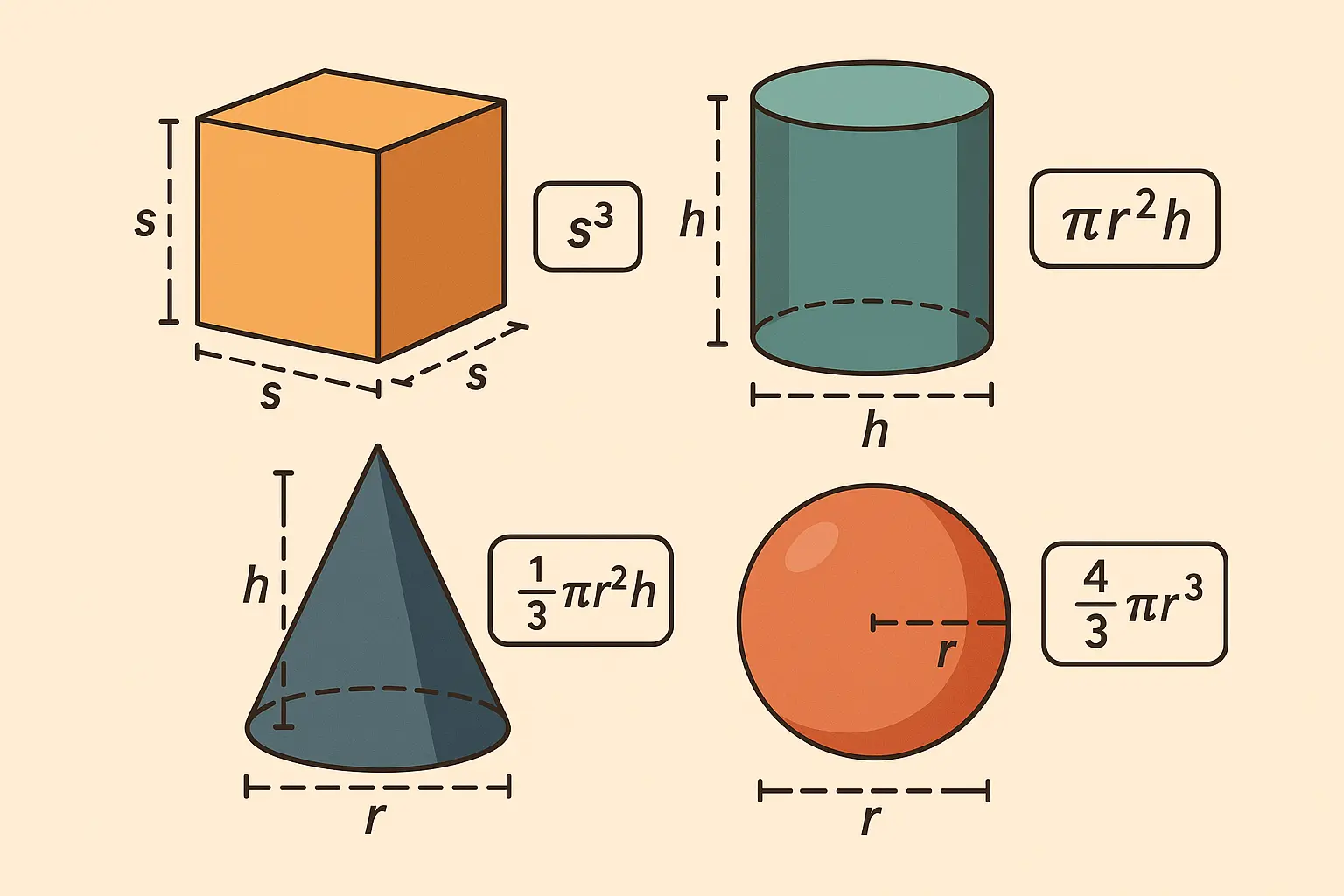

Cube Volume Calculators: Simple Yet Powerful

Honestly, cube calculations are my favorite because they’re so straightforward. You measure one side, plug it in, and the volume of a cube calculator does the V = s³ math for you. No fuss, no multiple measurements to worry about.

According to Calculator.net’s Volume Calculator, cube volume calculations follow the simple formula V = s³, where s represents the edge length, making it one of the most accessible volume calculations for beginners and professionals alike.

The real lifesaver is the built-in unit conversion features. You can measure in inches and get your answer in cubic feet, or go metric and get imperial results. I can’t tell you how many headaches this has saved me on projects where everyone’s using different units.

Getting Accurate Cube Measurements

Here’s where I learned the hard way – make sure you’re measuring actual edges, not diagonal distances. Sounds obvious, but when you’re rushing on a job site, it’s easy to mess up. Also, double-check that your “cube” is actually square. You’d be surprised how many “cubes” are slightly off.

Temperature matters too, especially with metal. Materials expand and shrink, so if precision is critical, factor that in. Modern volume calculator systems can handle this if you give them the right info.

Real-world example: A construction manager needs concrete for foundation blocks. Each block is 2 feet on all sides. Using V = s³, that’s 2³ = 8 cubic feet per block. For 50 blocks, you need 400 cubic feet, plus 10% for waste – so 440 cubic feet total. Better to have too much than run short halfway through the pour.

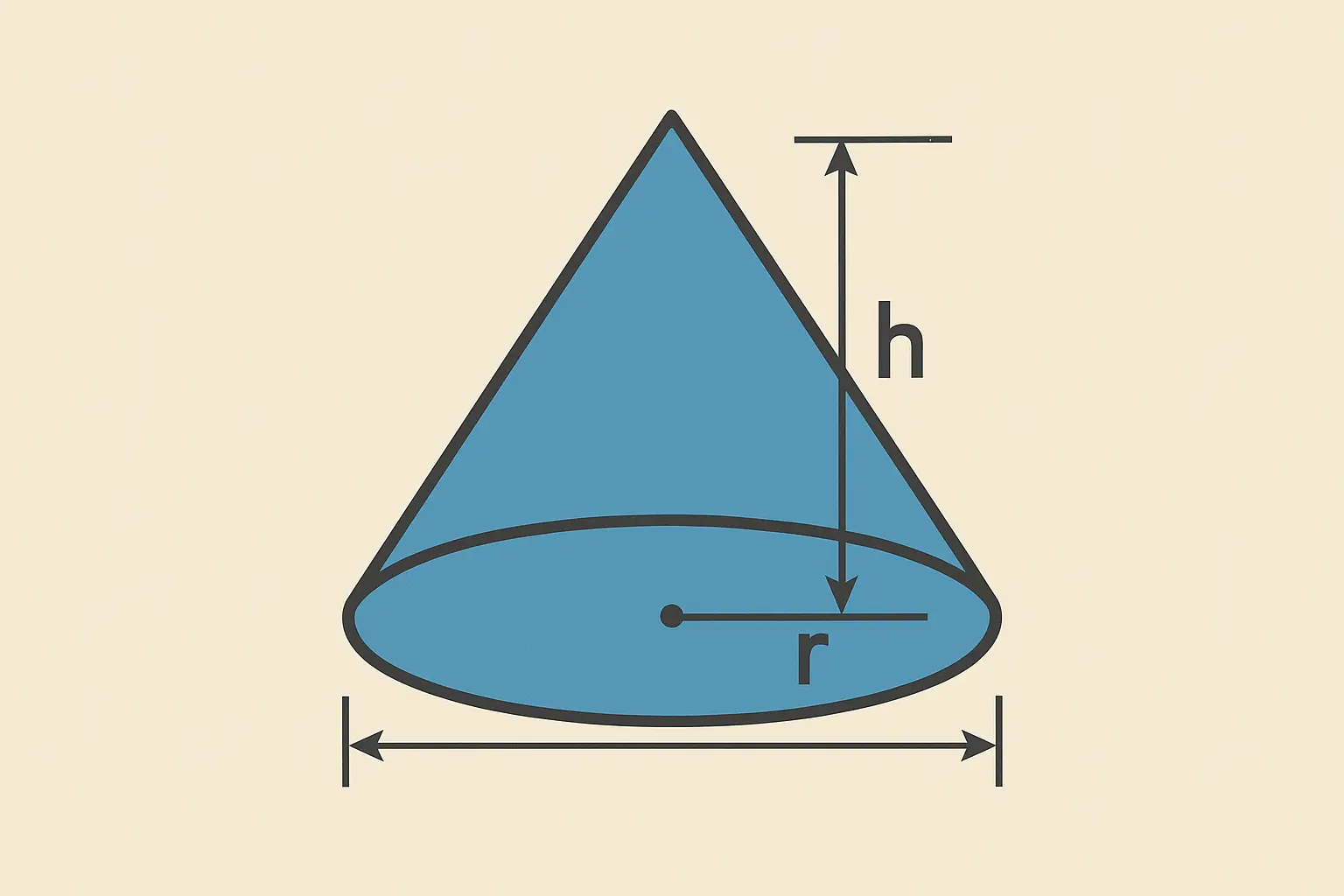

Cone Volume Calculations: Handling Complex Geometry

Now we’re getting into trickier territory. Cone volume calculator applications need both radius and height measurements, and here’s the kicker – small measurement errors get magnified in the final result because of how the math works (V = (1/3)πr²h).

The tricky part is measuring the radius accurately. You need to find the true center of the base circle, and if your base isn’t perfectly circular, you might need to calculate an equivalent radius based on the actual area. It’s more art than science sometimes.

Based on Omni Calculator’s volume formulas, cone volume calculations use the formula V = (1/3)πr²h, where r is the radius and h is the height, requiring precise measurements of both dimensions for accurate results.

Advanced Cone Calculation Features

Truncated cones (frustums) are where things get really complex. You need both top and bottom radii, and the formula V = (1/3)πh(r₁² + r₁r₂ + r₂²) shows why you want a good volume calculator handling this stuff.

Here’s something that trips people up – slant height versus perpendicular height. If you only have slant height measurements, you need to convert using the Pythagorean theorem before calculating volume. Smart calculators do this conversion automatically, which is a huge time-saver.

Tube Volume Calculations: Internal vs External Considerations

Tube volume calculator systems can get confusing fast because you need to know what you’re actually calculating. Are you figuring out how much fluid fits inside, or how much material you need to make the tube? For fluid capacity, you want internal volume using the inner radius. For material estimation, you need the difference between outer and inner volumes.

Wall thickness is where people mess up big time. I always double-check whether the specs give me internal diameter, external diameter, or wall thickness measurements. Getting this wrong means ordering the wrong amount of material, and that gets expensive fast.

|

Tube Calculation Type |

Formula |

What It’s For |

Key Measurements |

|---|---|---|---|

|

Internal Volume |

V = πr²h |

How much fluid fits |

Inner radius, length |

|

Material Volume |

V = π(R² – r²)h |

How much material needed |

Outer radius, inner radius, length |

|

Pipe Flow Capacity |

V = π(d/2)²L |

Plumbing design |

Internal diameter, pipe length |

|

Structural Tubing |

V = π(D² – d²)L/4 |

Construction materials |

External diameter, internal diameter |

Advanced Container Volume Solutions

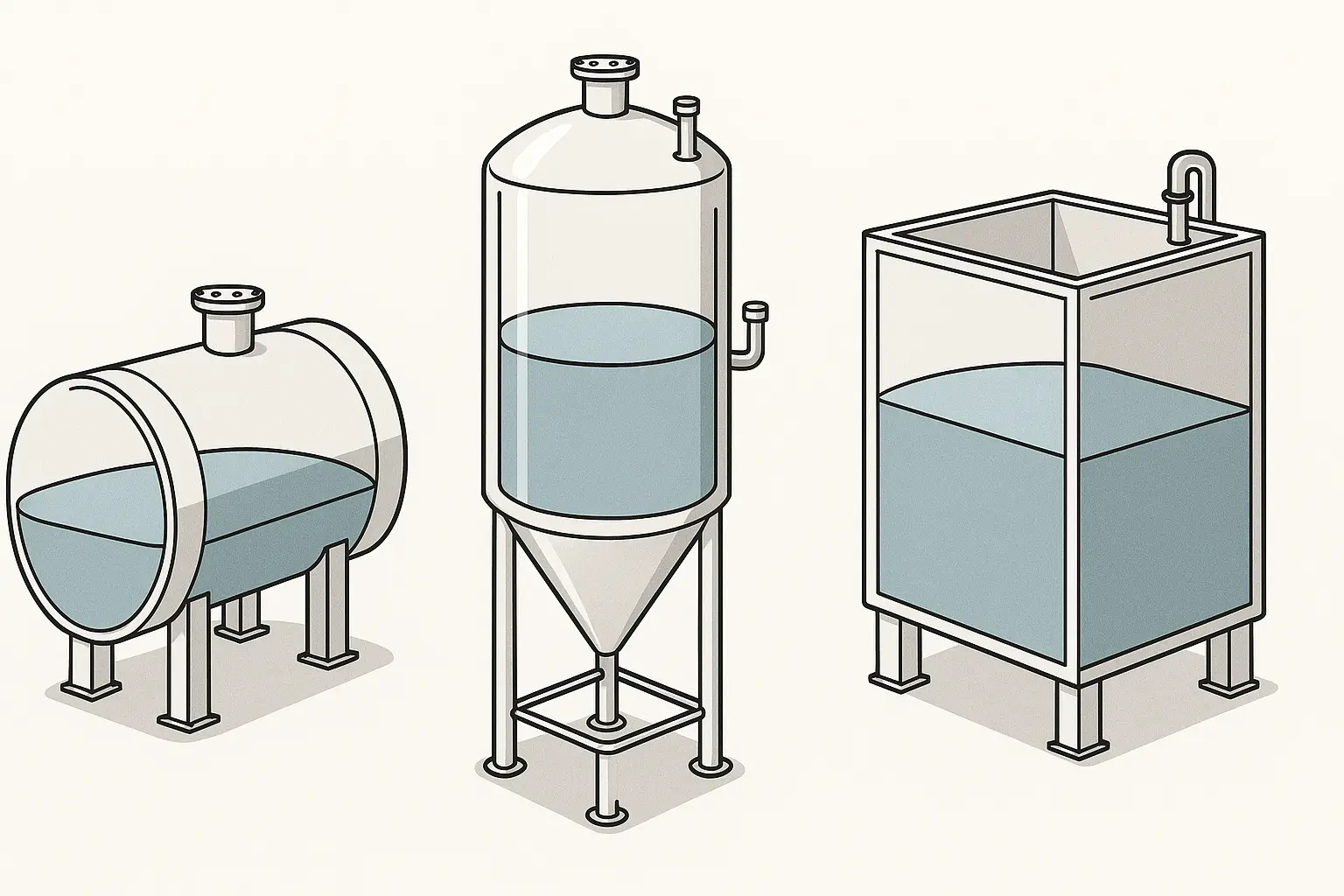

Tank Volume Calculators: Industrial Applications

Tank volume calculator applications get complicated real quick once you move past simple cylindrical shapes. Horizontal tanks are a nightmare for partial fill calculations, and vertical tanks might have weird bottoms or dished heads that throw off your numbers.

I’ve worked on projects where the difference between what the calculator said and what we could actually use was huge. Things like where the outlet sits, internal structures, and safety margins all eat into your usable capacity. Always factor in the real-world stuff, not just the theoretical volume.

Horizontal vs Vertical Tank Configurations

Horizontal tanks are the worst for partial fills. The volume doesn’t change evenly as the liquid level goes up – it’s all wonky math with segmented circles that most people can’t do in their heads.

Vertical tanks are more straightforward for regular fills, but throw in a conical bottom or dished head and you need specialized tools. Don’t try to force a general volume calculator to work for your specific tank setup. Trust me, it’s worth getting the right tool for the job.

Microsoft’s recent development of the “Storage Spaces Direct Calculator” demonstrates how technology companies are creating specialized volume planning tools for complex configurations, similar to how tank volume calculators must handle various geometric challenges in industrial applications.

Online Volume Calculator Platforms: Comprehensive Solutions

Web-based volume calculator online platforms are where it’s at. You get multiple shape options in one place, automatic unit conversions, and everything saves to the cloud. No more switching between different apps or losing your calculations when your computer crashes.

The calculation history feature has been a game-changer for me. You can organize everything by project, share results with your team, and keep detailed records for audits or future reference. It’s like having a filing cabinet that actually works.

According to CalculatorSoup’s volume calculator, online platforms can compute volumes for multiple geometric solids including capsules, cones, frustums, cubes, cylinders, hemispheres, pyramids, rectangular prisms, spheres, and spherical caps, providing comprehensive calculation capabilities in a single interface.

Advanced Platform Features

The measurement uncertainty analysis is pretty cool – it shows you how your measurement errors affect the final result. Super helpful when you’re working on critical stuff where accuracy really matters.

Batch calculations are a lifesaver for big projects. I’ve used this for construction jobs where I needed to calculate volumes for hundreds of similar components. What used to take days of manual work now takes minutes. Understanding data accuracy becomes critical when implementing automated calculation systems, similar to how businesses need comprehensive GA4 audit processes to ensure their analytics data maintains accuracy and reliability for decision-making.

Industry-Specific Volume Applications

Construction and Architecture Applications

Construction volume calculator applications aren’t just about basic geometry. When you’re estimating concrete, you need waste factors (usually 5-10% extra), pump line volumes, and you have to think about pour sequencing to make sure you don’t run short mid-pour.

HVAC sizing depends on getting room volumes right. I’ve seen systems that couldn’t keep up because someone botched the volume calculation during design. Undersized systems struggle, oversized systems waste energy and money.

Real example: An architect designing a conference room (30′ × 20′ × 12′ high) gets 7,200 cubic feet. For proper HVAC, you need 6-8 air changes per hour, so the system has to handle 43,200-57,600 cubic feet per hour. Get that wrong, and people are either freezing or sweating in meetings.

Material Requirements and Quality Control

Manufacturing relies on volume calculator systems for everything – material planning, storage space, production capacity. Small errors cascade into material shortages or expensive overstock sitting around taking up space.

Quality control uses volume calculations to verify specs and catch defects. When dimensional tolerances translate to volume tolerances, accurate calculations become critical for maintaining quality standards. Effective quality control systems require comprehensive measurement strategies, much the same way businesses need systematic approaches to market sizing for business opportunities to ensure accurate data collection and analysis for strategic planning.

Chemical and Process Industries

Chemical processing needs specialized volume calculator applications that account for temperature, pressure, and chemical properties. Process vessel sizing involves safety factors, thermal expansion, and regulatory compliance – it’s not just basic geometry anymore.

Inventory management in chemical industries is serious business. You need precise volume tracking for regulatory compliance and safety stock management. Automated reordering systems depend on accurate volume measurements to keep appropriate inventory levels without over or understocking dangerous materials.

The development of specialized medical calculators, such as the “topical medication volume calculator” by Larry Eichenfield, MD, demonstrates how volume calculation tools are becoming increasingly specialized for industry-specific applications, similar to how chemical industries require customized volume tracking systems for regulatory compliance and safety management.

Digital Integration and Automation Features

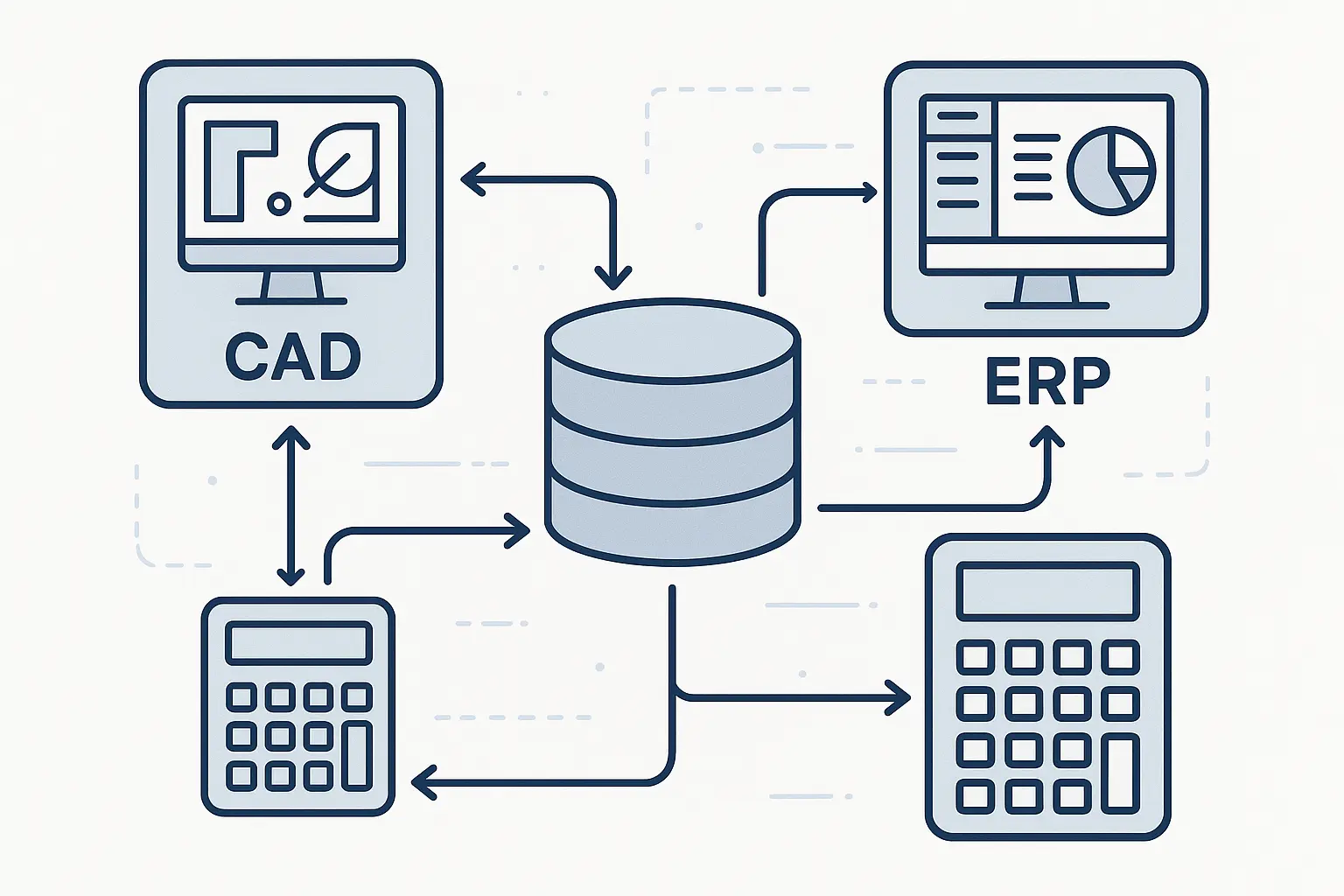

API and Software Integration

API integration is where volume calculator systems really shine in business environments. You can connect them with your ERP system, eliminate manual data entry, and reduce calculation errors. When your design changes, material requirements update automatically.

CAD software connectivity is huge for design workflows. Export dimensions directly from your design program to the volume calculator, then import results back for material specs and cost analysis. No more manual data transfer and the errors that come with it.

Real-Time Calculation Systems

Dynamic parameter adjustment means instant recalculation as dimensions change. Great for iterative design and “what if” scenarios. You can see immediately how design changes affect material requirements and costs.

Batch processing becomes essential for large projects. Enterprise systems can handle thousands of volume calculator operations simultaneously, which is critical when you’re dealing with manufacturing or construction projects with tons of different components. Implementing automated systems requires careful consideration of optimization strategies, similar to how businesses must understand AI search engine optimization tools to maximize their digital presence through intelligent automation and data processing.

|

Integration Feature |

Benefits |

How Hard to Set Up |

Payback Time |

|---|---|---|---|

|

API Connectivity |

No manual entry, fewer errors |

Medium effort |

3-6 months |

|

CAD Integration |

Smooth design workflow |

High effort |

6-12 months |

|

ERP System Sync |

Auto material planning |

High effort |

6-18 months |

|

Real-time Updates |

Faster decisions |

Easy |

1-3 months |

|

Batch Processing |

Handle big projects |

Medium effort |

3-9 months |

|

Mobile Access |

Field calculations |

Easy |

1-2 months |

Best Practices for Accurate Measurements

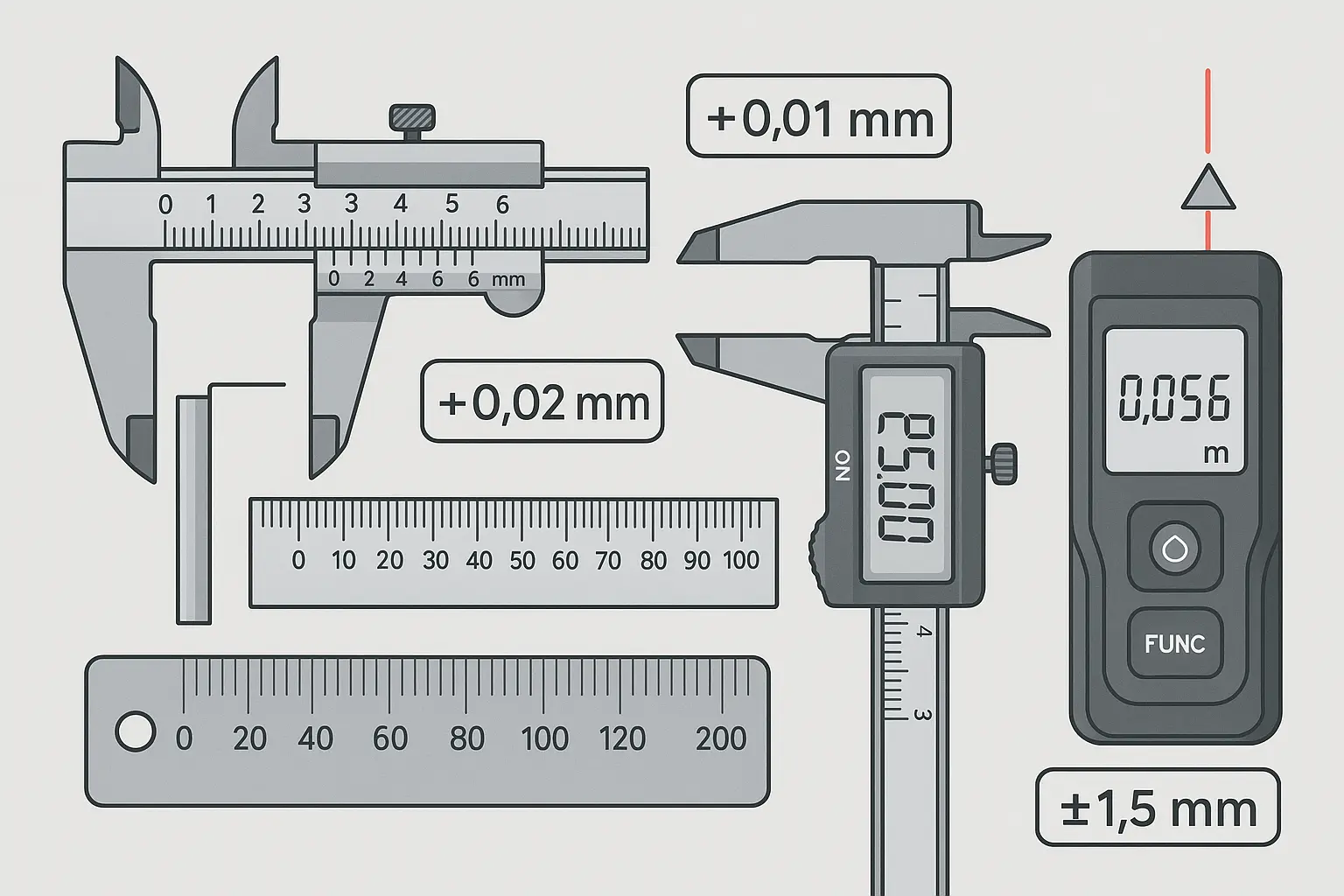

Measurement Tool Selection and Accuracy

Choose your measuring tools based on how precise you need to be. High-precision work needs calibrated instruments and consideration of thermal expansion. Don’t just grab whatever measuring tool is handy – match the tool to the job requirements.

Here’s something that bit me early on – small measurement errors compound in volume calculator applications, especially for shapes requiring multiple dimensions. Understanding how errors add up helps you focus your precision where it matters most.

Calculator Selection and Verification

Pick your volume calculator based on what you actually need to do. Basic geometric calculations need different features than specialized container calculations or partial fill calculations. Don’t choose based on flashy features you’ll never use.

Always verify your calculations through alternative methods or cross-reference with known volumes. Set up quality control processes for volume calculations to prevent costly errors in material ordering or capacity planning.

Real example: A chemical plant engineer calculated 15,000 gallons for a horizontal storage tank, but verification with water filling tests showed only 14,200 gallons due to internal baffles and outlet positioning. That 5.3% difference matters for capacity planning and regulatory compliance.

Mobile Application Development and Field Use

Custom Mobile Apps for Volume Calculations

Mobile apps combine measurement tools with volume calculator functionality in ways desktop platforms can’t touch. Device cameras can estimate dimensions using AR features, while GPS integration helps with location-based material delivery calculations.

I’ve used mobile volume calculator apps on construction sites where immediate calculations determined whether we had enough materials to finish the day’s work. Being able to photograph objects, input rough dimensions, and get instant volume estimates streamlined field decisions significantly.

Real-World Mobile Implementation

Construction crews benefit from apps that store calculation history offline, sync with project management systems, and generate material order lists directly from volume calculator results. Weather resistance and battery life become critical for field applications.

The measurement uncertainty features in mobile apps help field personnel understand when their quick estimates are good enough versus when they need more precise measurements. This prevents both over-engineering and costly mistakes.

Packaging Optimization and Logistics Applications

Shipping and Container Utilization

Packaging optimization uses volume calculations to maximize container fill rates and cut shipping costs. I’ve worked with logistics teams where improving container fill rates by just 5% resulted in significant annual savings due to fewer shipments needed.

Three-dimensional packing algorithms rely on accurate volume calculator operations for individual items and containers. These systems figure out optimal arrangement patterns, account for fragile item protection, and calculate weight distribution for safe transport.

Automated Warehouse Systems

Automated storage and retrieval systems depend on precise volume calculations for inventory placement and space optimization. Warehouse management systems use volume data to determine storage locations, calculate picking routes, and optimize inventory turnover.

Dynamic inventory management adjusts storage allocations based on seasonal volume changes and product mix variations. Volume calculator systems drive these adjustments, keeping warehouse space utilization optimized as inventory composition changes throughout the year.

Choosing the Right Calculator Platform

Integration with Existing Workflows

Look at how volume calculators integrate with your existing systems – documentation, CAD software, inventory management. Seamless integration reduces workflow disruption and increases adoption rates across teams. Nobody wants to learn a completely new system that doesn’t play nice with what they’re already using.

Mobile-responsive designs enable field use, allowing on-site volume calculator operations without heading back to the office. This proves especially valuable for construction, inspection, and maintenance applications where immediate calculations support real-time decision-making.

Advanced Features and Collaboration

Team collaboration features let multiple users work on volume calculation projects simultaneously, sharing results and maintaining consistent calculation standards across organizations. Project organization capabilities help manage complex calculations involving multiple components or phases.

Export functions for documentation ensure volume calculator results integrate with reporting systems and project documentation requirements. Platforms with robust export capabilities save tons of time by eliminating the need to reformat results for different stakeholders.

How The Marketing Agency Can Help

Businesses that rely on volume calculations for operations often struggle with digital marketing that actually speaks to their technical expertise. The Marketing Agency gets the precision and accuracy requirements that drive industries like manufacturing, construction, and chemical processing.

We develop targeted marketing strategies that show deep technical understanding while driving measurable business growth. Our data-driven approach to marketing mirrors the precision you require in volume calculations, ensuring your marketing investments deliver quantifiable ROI just like your volume calculations deliver accurate measurements.

Ready to connect with customers who value precision and technical expertise? Contact The Marketing Agency to develop marketing strategies that speak your technical language while driving real business results.

Final Thoughts

Volume calculators have transformed from simple math tools into sophisticated digital platforms that integrate with entire business ecosystems. The evolution from manual calculations to automated, cloud-based systems reflects broader technological advancement while addressing fundamental business needs for accuracy and efficiency.

Success with volume calculations comes down to matching tool capabilities to your specific needs, understanding measurement accuracy implications, and implementing proper verification procedures. Whether you’re calculating concrete volumes for construction projects or sizing process vessels for chemical applications, the principles remain the same – accurate measurement and appropriate tool selection.

The future of volume calculation lies in deeper integration with business systems, enhanced mobile capabilities, and more sophisticated error analysis features. As these tools continue evolving, they’ll become even more essential for industries requiring precise spatial measurements and capacity planning.